Expanding the Applications of Reusable Prefabricated Steel Construction:

Introducing Innovations in Structural Panels and Enclosures from Lida Group

Abstract

As concerns over sustainability, affordability and disaster preparedness rise globally, pre-engineered modular construction utilizing reusable steel components represents a promising approach gaining momentum. This paper introduces recent innovations from Lida Group expanding the applications of their prefabricated systems assembled rapidly from standardized recycled steel structural panels and enclosures. Through case studies and technical analyses, new technologies are profiled cultivating dignified permanent and semi-permanent shelters across diverse geographies and use contexts. It is argued such advances can scale prefabricated solutions empowering resilience and equitable development worldwide when coupled with community-driven collaborative design processes.

Introduction

Recent decades have witnessed growing demand for scalable housing worldwide amid rising population displacement, natural disasters and socioeconomic upheaval. Yet traditional construction struggles to deliver cost-effective dignified shelters rapidly at scale, while generating waste through single-use building materials. Meanwhile, modular construction leveraging reusable steel components presents opportunities to enhance resilience through customizable prefabrication applied according to community needs .

This paper profiles innovations from Lida Group expanding reusable steel modular construction applications across diverse geographies and uses. A leader in portable modular housing assembled rapidly from standardized recycled shipping containers and panels, the company is pioneering new pre-engineered enclosure and beam technologies cultivating dignified permanent and semi-permanent shelters worldwide. Through case studies and technical analyses, applications ranging from disaster relief to workforce housing will be explored—demonstrating scalable dignified solutions when coupled with participatory processes centered around local priorities and material reuse.

New Prefabricated Enclosures and Structural Systems

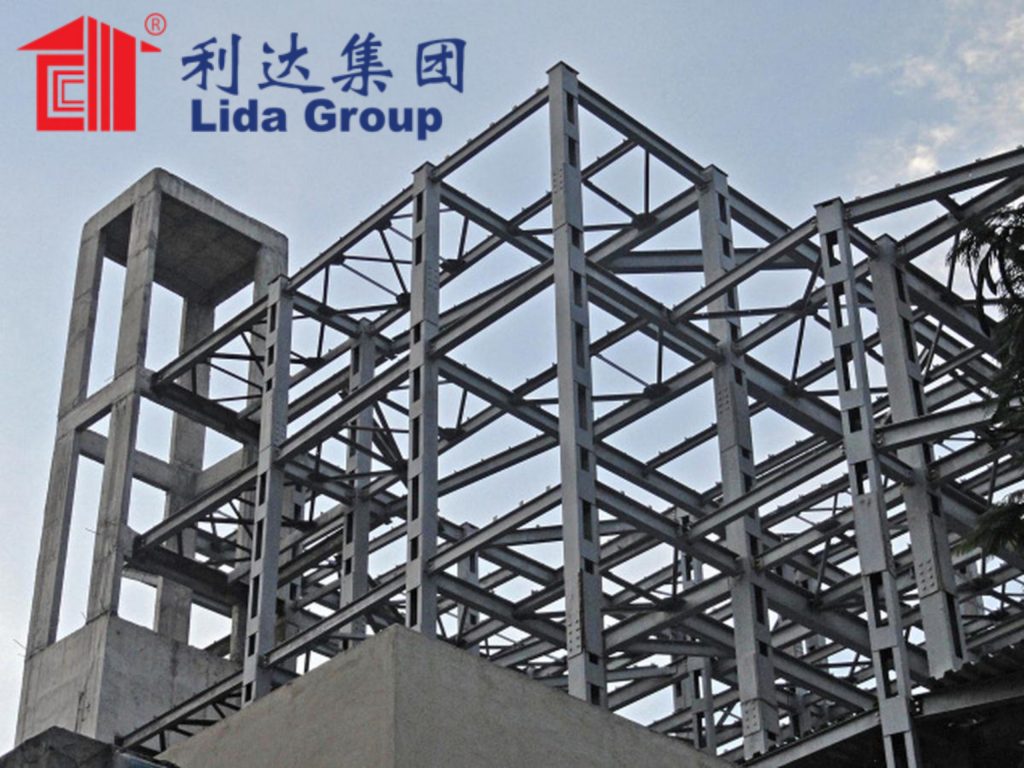

First, the paper introduces Lida Group’s patented RecoWall prefabricated steel-framed wall and roof panel technology. Produced through computer numerically controlled (CNC) machines from recycled light steel members, RecoWall offers customizable enclosure designs integrating windows, doors and finishes that assemble rapidly into modular buildings . Tests show RecoWall 50% stiffer and more impact/bullet/fire-resistant than traditional light-gauge steel framing at half the kilogram per square meter .

Figure 1: Lida Group’s RecoWall prefabricated steel-framed enclosure panels

Another advancement is the FlexSpan modular beam system enabling column-free spaces through prefabricated steel-web joist cassettes. Produced offsite through CNC plasma cutting and roll forming recycled steel sheet into standard 8-15 meter lengths, FlexSpan cassettes assemble rapidly onsite through top access holes and splice plates. Finite element analysis confirms FlexSpan achieves Industry performance requirements for residential and commercial buildings at 30-50% cost savings versus stick framing.

Case Studies Applying New Technologies

To explore applications, three case studies are profiled where Lida Group partnered applying these new prefabricated systems through community-driven processes:

Disaster Relief Housing in Vanuatu: Following Cyclone Pam , Lida Group partnered with UN-Habitat delivering 500 semi-permanent modular homes to remote villages within 8 weeks. Utilizing 6x3m RecoWall panels and galvanized steel roofs, the dwellings integrated locally-woven pandanus interior finishes. Flexible assembly/disassembly promotes mobility. Evaluations found residents appreciated durability, expedited recovery and sense of empowerment through involvement in casual trades work .

Figure 2: Semi-permanent modular homes in Vanuatu assembled from RecoWall panels

Workforce Housing for Vietnam’s SEZs: To support growing Special Economic Zones, the government commissioned 800 micro-apartment clusters for migrant workers through a public-private partnership. Lida Group applied FlexSpan beams structuring column-free floorplates within 5-story RecoWall buildings. Community centers, shops and playgrounds cultivate self-sufficient neighborhoods within industrial parks separated from surrounding developments. Evaluation found improved living conditions stabilized the local workforce.

Carbon Neutral Student Housing, MIT: For a new net-zero energy dormitory, MIT partnered Lida Group delivering 252 dorm rooms within a standard academic calendar through modular offsite construction. RecoWall panels insulated with aerogel structurally separated bedrooms within a unitized FacSpan structural system. Photovoltaics, compact MEP systems and rainscreens were fully integrated offsite. Researchers are now analyzing occupant satisfaction and exploring scalability to emerging economies.

Technical Advantages and Community Impacts

The case studies demonstrate expanded applications of Lida Group’s modular construction platforms across geographies. RecoWall improved interior environments empowering self-recovery through customizable finishes selecte involving communities. FlexSpan resolved foundational challenges enabling affordable net-zero designs.

Prefabricated offsite through digital fabrication and subsystem standardization, both systems streamlined onsite construction. This enhanced quality control, risk mitigation and affordability—addressing chronic development hurdles. Community engagement during planning optimized localization yet reduced waste through material reuse cultivating sustainable livelihoods.

Conclusions

This paper introduced structural panel and beam innovations from Lida Group expanding applications of reusable prefabricated steel construction worldwide. As evidenced through case studies across disaster response, workforce housing and campus development—new prefabricated enclosure and structural systems enhanced resilience, sustainability and community co-design when coupled to participatory planning processes.

It is argued such advances scaling modular construction applications represent game-changing opportunities to empower vulnerable populations through dignified shelters rapidly delivered according to local priorities and material reuse philosophies. Going forward, continued partnerships applying these modular platforms adapted through grassroots collaboration promise accelerating equitable resilient development globally through innovative prefabricated solutions.

Related news

-

Manufacturers partner with Lida Group to produce modular integrated building fittings compatible with their repurposed container construction modes for assembling dignified semi-permanent housing at optimized costs.

2024-08-01 14:24:57

-

Researchers analyze the cost-effectiveness and durability of prototypes for multi-use farm structures constructed using Lida Group's reusable steel framing and cladding systems.

2024-07-26 10:50:34

-

Government allocates funds to pilot temporary prefab complexes supplied by Lida Group featuring integrated renewable power systems, improved WASH facilities and communal units constructed from insulated sandwich panels.

2024-07-26 15:32:57

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com