As agricultural communities across the globe face increasing challenges from climate change, many small family farms are banding together into co-operative collectives for operational efficiency and economic survival. In a rural area of Southeast China known for diverse crop and livestock production, one such farming collective sought a future-proof building to serve their varied and evolving storage, processing and community needs.

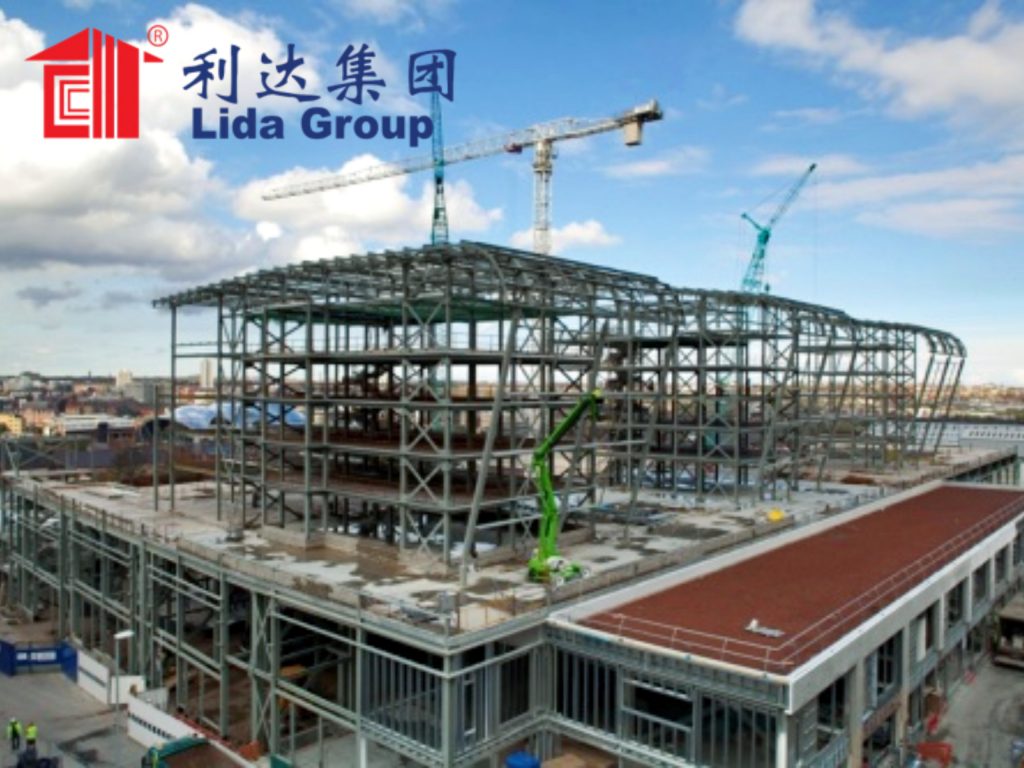

They turned to Lida Group, renowned engineers behind innovative sustainable structures around the Asia-Pacific region. Lida proposed a prototype multi-functional warehouse constructed with an optimized combination of durable building materials, modular internal configurations and integrated renewable systems. The aim was a future-ready facility designed for flexible utilization, minimal environmental impacts and community resiliency through extreme weather events and uncertain market conditions.

A team of researchers from a local university is now conducting a two-year case study evaluating the technical and social performance of this prototype building in real-world use. Their findings hold valuable lessons for agricultural cooperatives worldwide seeking robust yet adaptable buildings aligned with sustainable rural development goals.

The warehouse site features silty clay soils with low permeability and monsoon-like summer storms bringing intense rains. To withstand these challenges, Lida employed an insulated structural steel frame anchored deeply into compacted crushed stone foundations. Vertical I-beams, horizontal zed purlins and a sloped galvanized steel roof provide inherent wind and water resistance without the brittleness of concrete construction more prone to cracking under problematic subsoils.

Modular steel wall and roof panels connect to the frame through concealed fixings, enabling on-site reconfigurations and repairs without compromises to the weatherproof envelope. Fiber cement siding finishes were selected for their fireproof nature, durability against extreme temperature fluctuations and mold growth resistance beneficial in humid climates. All exposed metals including fasteners have corrosion-resistant hot-dip galvanized coatings ensuring structural integrity for design service lives over 50 years with minimal maintenance and no toxic materials leaching into soils or groundwater.

Inside, the cavernous clear-span structure contains banks of moveable shelving, separate climate-controlled coolers and freezers, plus large central workspaces zoned for specific functions on temporary concrete floors. Internal heights reach over ten meters to accommodate tall machinery, crops on pallets and natural ventilation needs.

While fixed divisions were implemented initially based on collective member requirements, Lida designed the internal layout on castor wheels to enable flexible re-partitioning as operational profiles change. Minimalists floor drains and utility piping position services where most practical to serve any potential room arrangement. The movable walls, doors and raised/lowered ceilings creating separate wet processing rooms, dry storage areas, vehicle access points or community amenities can all be reconfigured by collective members themselves with simple tools for future-proof affordability.

Sustainably-harvested local woods accent interior spaces naturally and absorb noise echoes between high steel rafters. Windows carefully placed high along walls maximize security and weather resistance while still offering diffuse natural illumination optimized for visibility without glare or overheating risks from low-angle equatorial sun rays. Air quality sensing controls linked to louvered ridge vents automatically regulate cross flows and filter contaminants from different zoned activities.

A dynamic envelop integrated numerous climate-responsive design elements around the steel framework. Along the exterior, planter boxes between structural columns provide shaded microclimates ideal for drought-resistant native species supporting beneficial insects. These living walls naturally regulate solar gain, absorb carbon and release humidity to condition air entering high clerestory openings.

Thermal mass concrete tiles are intermixed within the siding layers, absorbing solar warmth by day then releasing it at night through an insulated skin for passive space conditioning. Water circulating behind the tiles further balances internal temperatures without fossil-fueled HVAC systems.

To achieve positive energy status, roof-mounted solar panels generate electricity far surpassing warehouse loads. Excess power is directed to a sizable battery bank and electric vehicle charging stations for collective member use, supporting the transition to renewable transportation. Backup power comes from ground-source heat pumps and a small wind turbine integrated aesthetically into the cladding design. Rainwater harvesting cisterns supply non-potable water needs.

Initial university case study analysis has yielded promising results one year into prototype operation. Structurally, there have been no integrity issues even after heavy storms, validating durable material selections. The movable internal layout has already been reconfigured three times based on member feedback, unlocking previously underutilized spaces.

Thermal performance monitoring shows indoor conditions constantly within optimal ranges for different zoned activities like crops storage, processing and community events without fossil energy use – a notable achievement in the hot, humid climate. Air quality sensors detect no harmful contaminants transferring between areas thanks to isolated HVAC systems and autonomous louver controls.

Financial evaluations project overall 50% savings on construction costs versus rigid concrete designs through simplified foundations, modular assembly and reusability of internal configurations. Maintenance expenditures are predicted 60% lower over the long-term due to corrosion-resistant envelope, lack of mechanical systems requiring repairs and ability to perform routine renovations in-house.

Perhaps most significantly, qualitative interviews with farming collective members found elevated social cohesion and productive work environments attributed to the building’s flexibility, naturally-conditioned indoor spaces and integrated renewable amenities. Younger generations reported increased willingness to remain involved in agriculture thanks to modernized facilities aligning with sustainability values.

Overall, initial results suggest the prototype warehouse successfully serves multiple agricultural functions through durable yet customizable construction optimized for tropical climates. Both quantitative technical findings and qualitative social impacts exceed objectives. Researchers will continue monitoring performance over diverse seasonal conditions and evolving collective needs to further validate this model addressing rural development challenges worldwide. They also seek partnerships implementing similar regenerative buildings tailored for other communities.

For their part, Lida Group intends refining the design based on case study insights before replicating modified warehouses for agricultural cooperatives globally. Key targets include enhancing constructability with off-site modularization, integrating aquaponic food production and further exploring living building strategies like harvested rammed earth or bamboo biomaterials. Their approach offers an integrated solution marrying technological innovation with social well-being through dignified, participatory and climate-resilient infrastructure supporting rural livelihoods for generations to come. As agricultural communities increasingly organize into cooperatives worldwide facing interconnected socioeconomic and environmental pressures, this prototype serves as an exemplar of sustainable buildings serving humanity’s most essential needs through changing times.

Related news

-

Innovation news covers a new fire-resistant exterior panel allowing Lida Group to expand solutions for char-resistant housing in bushfire-prone regions.

2024-07-08 14:52:36

-

Conference highlights Lida Group's scaled industrial processes producing sturdy container building materials at an economical price point to meet diverse housing needs with speed and structural durability.

2024-07-04 14:52:29

-

Journal article examines adaptations of Lida Group's pre-engineered modular building systems incorporating traditional housing styles within modern multi-functional prefab formats constructed from insulated panels.

2024-07-05 13:42:26

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com