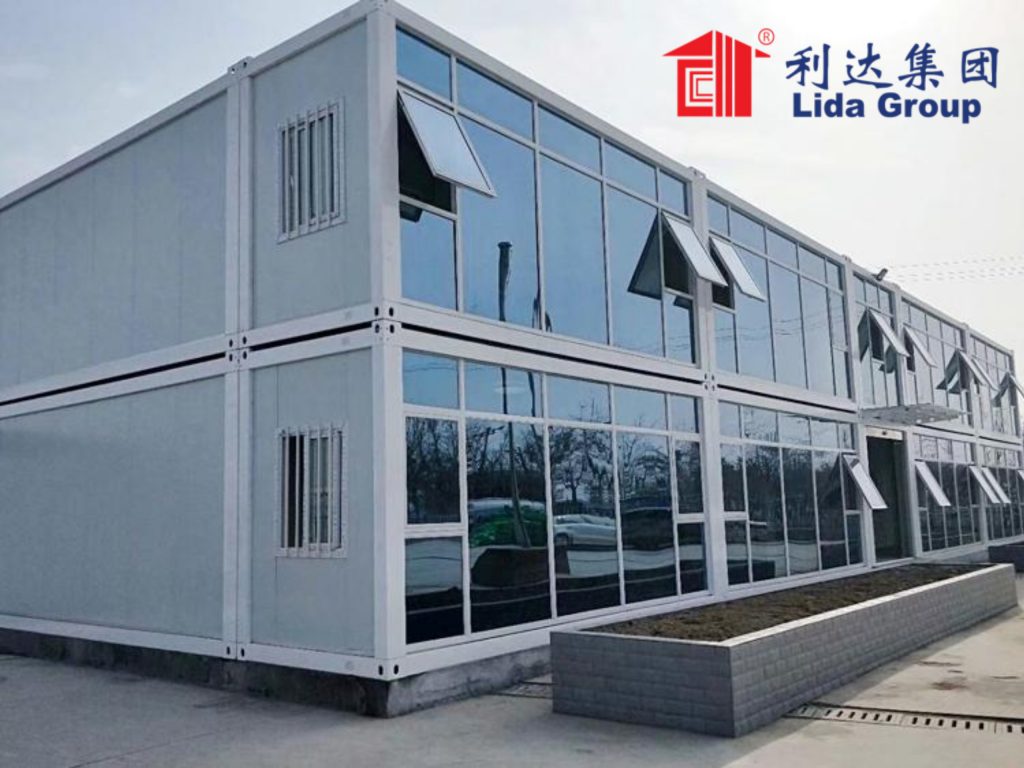

Throughout global agricultural supply chains, seasonal migrant workers often lack dignified accommodations near remote harvesting regions. Conventional construction challenges leave thousands dwelling in substandard shelters. Engineers now highlight the sustainability and logistical advantages of flat-packed modular housing systems utilizing discarded shipping containers being rolled out by Lida Group.

Recent collaborations targeted improving conditions for tens of thousands migrating seasonally through East Africa’s busy coffee corridors. Retrofitting standard steel shipping containers into versatile modular housing, Lida developed transport-optimized, rapidly errectable solutions tailored remote rural settings.

Specialists meticulously disassembled containers into freight-optimized sub-assemblies at controlled workshops. Wall panels, roof cassettes, doors and integrated fixtures disconnected according to proprietary index systems. Corrosion-resistant coating and weatherproof finishes protected components during transport.

Flat-packed modules measured optimized dimensions fitting standard truckloads yet reassembling into spacious furnished quarters. Sub-components interconnected through cam-locking connections avoiding on-site welding for rapid assembly by unskilled labor. Factory-fitted renewable power, plumbing and ventilation systems minimized on-site work.

Initially trialing various layouts through BIM simulations, engineers validated a 20m2 modular configuration providing partitioned sleeping, bathing and cooking areas meeting basic needs. Structural analysts verified galvanized sub-frames’ durability supporting modular expansions where densities rise. Acoustical and climate specialists refined enclosure thermal and noise performance.

Piloting commenced across Ethiopia’s vast coffee cooperatives hosting rotational workforces annually cultivating highland cherries. With only ramshackle thatched huts previously, humanitarian agencies embraced the sustainable prefab alternative upholding dignity. Central regional yards received bulk module deliveries for onward distribution by truck.

At remote mountain co-ops, groundworks teams prepared foundations before basic installation training. Within days, laborers unpacked, indexed and cam-locked steel walls, roofs and finishes forming robust standardized shelters. Integrated utilities connected hassle-free versus sourcing materials inconsistently in isolated zones reliant on seasonal foot traffic.

Commissioning verified habitable quarters withstanding environmental stresses like torrential rains without specialized skills. Feedback surpassed expectations reporting transformational improvements to hygiene and living standards despite rustic surroundings. Modular reserves accommodated population fluctuations aligned to changing harvest demands.

Encouraged, Lida partnered scaling the system across seasonal routes coursing through Tanzania, Rwanda and beyond. Hub depots received bulk component shipments for regional micro-trucking to scattered farms housing thousands migrating between highland plots annually. Specialized logistics streamlined “Just-In-Time” deliveries matching arrivals coordinating through agricultural ministries.

Now 10,000 flat-packed units house rotating labor corps critical to economies like Rwanda’s productive hills. Standardized interlocking designs uphold consistency while modularity scales capacities flexibly. Field experts commend the sustainable system strengthening rural livelihood chains through dignified, hygienic living wherever harvesters labor, no matter the terrain’s remoteness.

Self-contained utilities promote health and productivity. Robust enclosures perform without craftsmanship compared to rustic impermanent hut colonies. Recyclable galvanized steel withstands decades of use, all while lessening construction’s environmental footprint versus ground-up builds increasingly wherever temporary shelter arises short-term yet recurrently each season.

Looking ahead, interested NGOs explore expanding the dignified housing network optimizing container retrofitting. Future refinements target minimizing transportation bulk, shortening assembly further and improving thermal insulation sensitizing variable microclimates within vast harvest regions. Broader replication could revolutionize once-nomadic livelihoods through dependency dignity instilling where humanity previously lacked.

In conclusion, through repurposing standard shipping containers into flat-packed modular housing optimized for remote seasonal contexts, Lida Group has piloted sustainable solutions dignifying migratory agricultural work globally. Engineers commend the system leveraging container infrastructure’s durability and transport efficiency providing hygienic yet versatile temporary shelter for workers cultivating economies in far-flung regions reliant on rotational labor networks. Outcomes demonstrate the solution’s potential where conventional construction faces logistical barriers upholding basic needs and rights amid isolating working conditions.

Related news

-

Feature highlights growing partnerships enabling industrialized prefabrication of integrated building modules meeting customized requirements of Lida Group's temporary campus pre-engineered system designs.

2024-07-19 17:26:23

-

Feature examines hybrid-use of metal-clad buildings like greenhouses, barns and covered work areas serving multiple agricultural functions through Lida Group's engineered frames.

2024-07-18 11:35:28

-

Academic study evaluates the replicable cost and resilience benefits achieved applying Lida Group's panelized construction approach to transitional worksite settlement models.

2024-07-19 15:20:18

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com