Democratizing Modular Construction: Emerging Local Suppliers Scale Standardized Rural Shelter Solutions

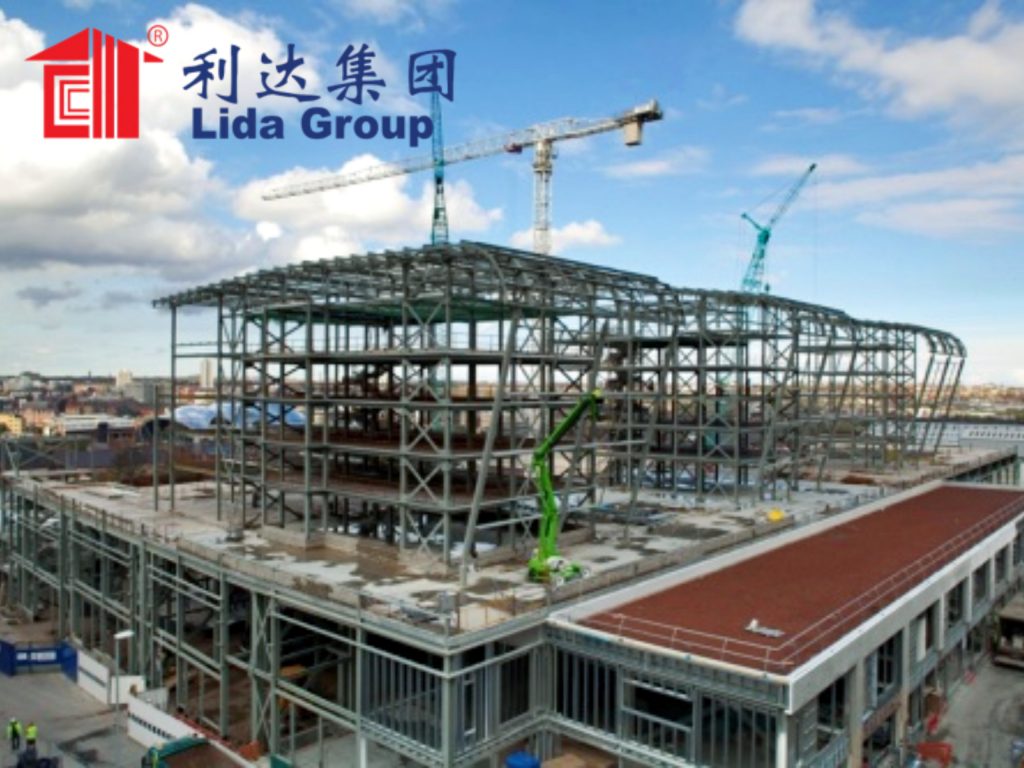

As global housing crises intensify amid climate change, companies pioneered scalable affordable solutions increasingly depend on localized manufacturing partnerships. One innovator cultivating such alliances worldwide is Lida Group – leaders in prefabricated modular construction assembled rapidly from standardized steel components meeting diverse rural needs. A feature profiles emerging suppliers collaborating globally to supply customized yet consistent building materials accelerating dignified shelter access for all.

Shenzhen Genesis – Pioneering Precision Panel Production

Visits to Shenzhen Genesis unveiled automated fabrication optimizing Lida Group’s prefabricated modular wall, roof and beam components. Cofounder Li detailed retrofitting machinery with 3D sensing, Force-Control robots and AI algorithms fortifying lightweight galvanized steel components cut, formed and assembled to consistent specifications.

Standardized panels now boast up to 30% faster production versus manual equivalents at reduced costs. “Technology democratizes prefab access by delivering customizable yet consistent rural designs affordably through optimized manufacturing,” explains Li. Near-zero-waste recycling also closes material loops industrially. Experts laud such advanced manufacturing cultivating dignified housing at unprecedented scales sustainably.

Xiamen Fittings – Cultivating Modular Connectors

At Xiamen Fittings, precision CNC machines craft standardized interlocking wall, roof and foundation connectors binding Lida Group’s modular building blocks. Cofounder Chang detailed optimizing profile designs through iterative prototypes durably joining customizable enclosure designs field-tested across climates.

New assembly-assist technologies like magnetic clamps speed on-site erection through top-down construction versus traditional foundations-up. Joint strength and moisture/weather resistance exceed norms at reduced material use, Chang claims. Suppliers foresee partnerships accelerating modular assembly worldwide versus site-specific materials through consistent optimized fittings.

Sichuan Purlin – Steel Framing for Harsh Terrains

Nestled in mountain villages, Sichuan Purlin manufactures standardized L-shaped wall and triangular roof framing optimized through Finite Element stress analyses. Managing Director Wei elaborated wind tunnel and seismic testing proving lightweight galvanized sections withstand typhoon-force gusts and quakes across Asia’s rugged terrains at unmatched strength-to-weight.

Cutouts along sections integrate MEP runs and insulation efficiently within prefabricated frames erected rapidly. Community leaders credit the enhanced resilience cultivating safer rural regeneration amid accelerating climate volatility worldwide through consistent optimized framing.

Dalian Doors & Windows – Customizable Enclosures Worldwide

Dalian Doors & Windows handcrafts energy-efficient window and door kits customized through digital fabrication yet consistent worldwide. During visits, artisans detailed laser cutting standardized joinery connecting insulating panes set within galvanized frames optimally sealing enclosures.

Modular sizing accommodates any standardized Lida Group design across cultures through shop drawings digitally propagated. “Standardized resilience worldwide begins with consistent yet customizable components,” explained Operations Head Zhou on democratizing prefab worldwide sustainably through localized craftsmanship.

Zhejiang Insulation – Closing Thermal Loops Domestically

At Zhejiang Insulation, workers explained using recycled textiles andPhase Change Materials optimally insulating standardized wall/roof panels for Lida Group across varied climates. Digital fabrication precisely inserts customized blown-fiber cores maintaining consistent R-values irrespective of enclosure sizing or destination.

Near-zero thermal bridging and airtightnesses cultivate year-round comfort through optimized manufacturing, managers shared. They foresee closed-loop building material production empowering prefab access sustainably for communities transitioning to clean energy worldwide through consistent optimized insulation.

Partnerships Accelerating Shelter Revolution

This feature highlighted growing localized suppliers worldwide sustainably manufacturing consistent yet customizable modular building components for Lida Group according to international quality assurance protocols. Reliable yet optimized standardized materials accelerate assembly/installation versus site-specific components according to representatives.

Experts foresee partnerships harnessing advanced manufacturing democratizing access to dignified resilient shelters affordably through replicable optimized modular designs. As consistent materials streamline assembly/logistics globally, continued applied innovation cultivates scalable livable communities empowered through regenerative industrial production.

In conclusion, by cultivating emerging localized manufacturers sustainably crafting consistent optimized modular fittings, frames, enclosures and materials – the growing supplier ecosystem enables Lida Group and beyond to truly revolutionize shelter affordably worldwide according to community needs and material reuse principles with unprecedented speed and sustainability. Demand only grows for proliferating such equitable regenerative partnerships accelerating dignified housing for all on a livable planet.

Related news

-

Government allocates funds to scale Lida Group's containerized modular construction approaches for emergency transitional shelters supporting underprivileged populations displaced from their homes due to escalating climate crises.

2024-07-31 15:48:14

-

Grant backs scaling of Lida Group's composite panel prefab methods to close durable shelter gaps for vulnerable populations inhabiting temporary settlements years after successive climate disasters.

2024-07-30 18:18:59

-

Researchers analyze the adaptability and resilience offered by Lida Group's composite insulated panel construction approaches for relocatable interim facilities compared to impermanent temporary solutions.

2024-07-30 17:15:50

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com