Overview of Prefabricated Container House Assembly

With their streamlined modular construction approach, prefabricated container housing presents a revolutionary alternative to traditional on-site building methods. By completing fabrication in temperature-controlled factories, these systems accelerate delivery of secure, durable shelter anywhere worldwide.

Precise installation procedures ensure rapid and efficient assembly with minimal on-site work. Detailed drawings provide step-by-step instruction to expedite deployment straight from delivery trucks. Adherence to schematics allows even inexperienced crews to complete turnkey housing in mere days versus months.

Prefabrication Off-Site

Container house modules undergo rigorous off-site fabrication under strict quality control. Steel freight containers form weatherproof structural enclosures outfitted with reinforced wall and ceiling panels incorporating insulation, utilities, fixtures and finishes.

Door and window openings integrate precision-fitted joinery. Shipping mounts secure modules for transport while removal enables on-site connection points. Indoor and outdoor styling maximizes curb appeal alongside durability and weather resistance.

Factory testing certifies systems integration, code compliance and longevity ahead of deployment. Components arrive sequentially packaged and sequentially numbered to simplify installation sequencing. Overall pre-engineering mitigates field modifications for maximum productivity.

Site Preparation

To accommodate container modules, job sites undergo minimal pre-installation tasks. These include surveying property, layout string lines to mark perimeter, excavate all foundation footers as per engineering plans’ dimensions and install reinforced concrete walls or piles.

Proper rough site grading ensures positive drainage away from all structures. Temporary utilities like power, water and sewer tie-ins establish service connections. Completion of utilities undergrounding minimizes post-installation disruption.

Installation Sequence

Systematic installation sequencing streamlines deployment based on pre-marked module numbers. Arriving modules place temporarily via crane or forklift on wood blocking along string lines. Per engineering drawings:

1. Position and plumb first module (module 1). Secure to footers with foundation bolts or anchors.

2. Install exterior siding, trim, fascia, soffits and other components per facade plan for module 1.

3. Position and connect next module (module 2) to module 1 via connector hardware at mating walls.

4. Follow above steps alternating module installation and connection until complete building assembled.

5. Install roofs, integrate skylights, ensure waterproofing at module junctions.

6. Fully connect utilities from rough-ins to modules’ interior finishes.

7. Confirm all hardware is tightened and structure is plumb, square and rigid prior to backfilling perimeter.

8. Complete landscaping, driveways per approved site plan.

Quality assurance inspections validate installation matches schematics and engineering specifications prior to occupancy. With standardized joining methods, experienced crews complete housing projects in mere days.

Modular Custom Homes

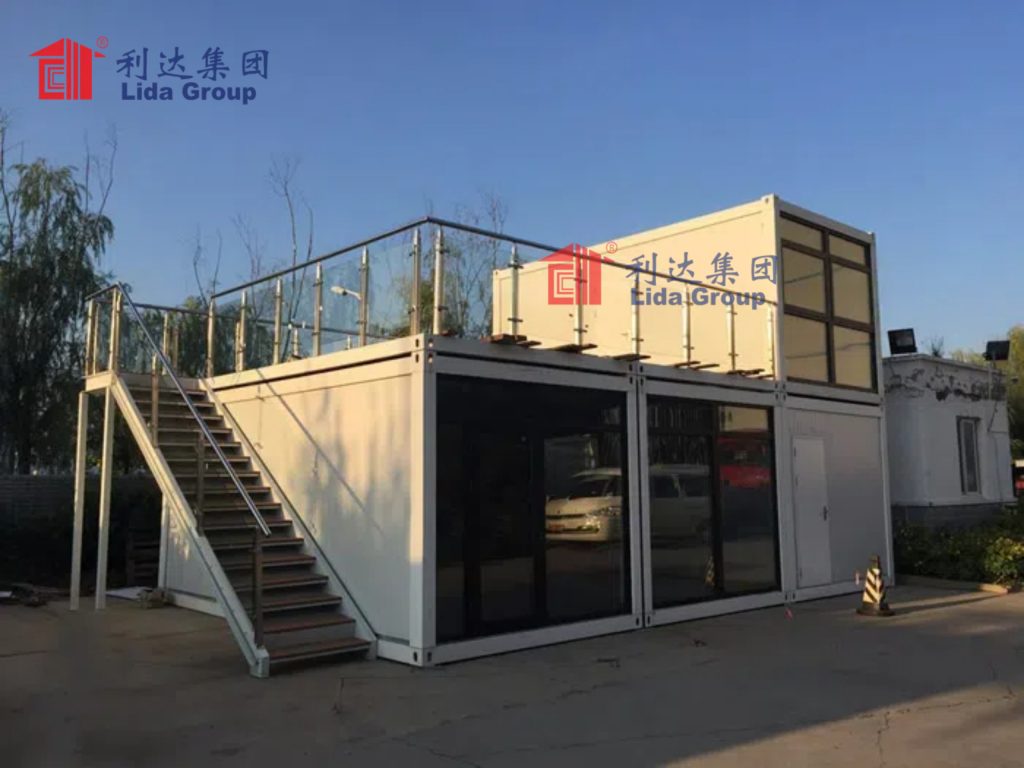

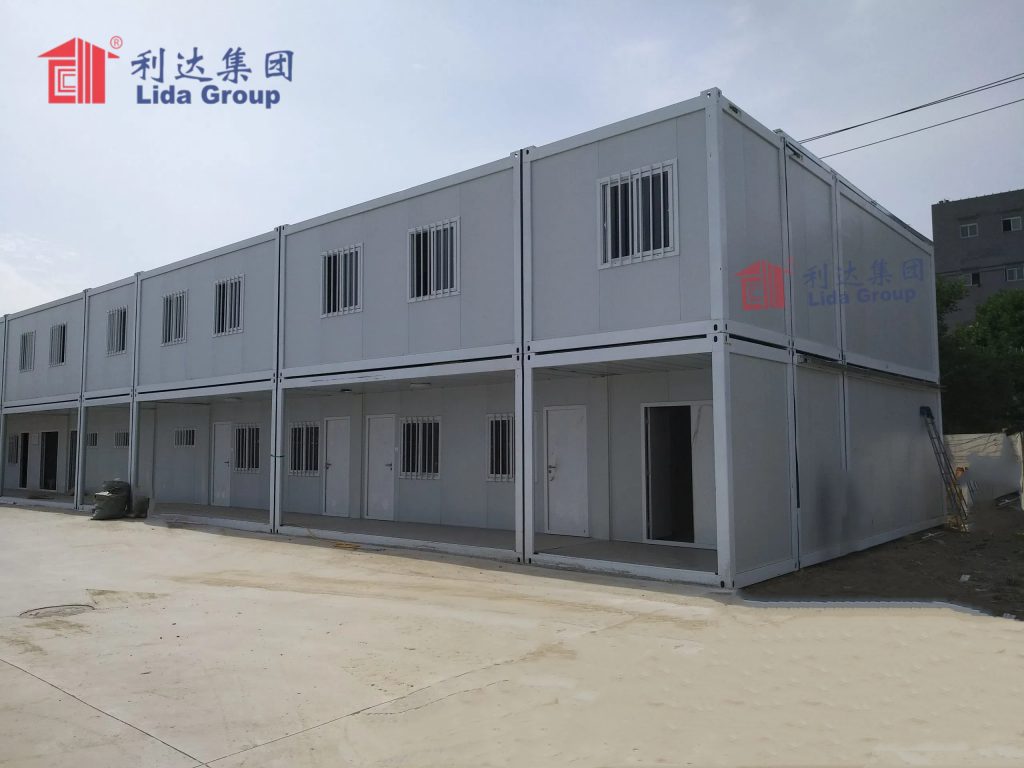

While factory-crafted for rapid assembly, container house modules accommodate infinite customizations. Internal spatial configurations scale from compact studios to multi-story estates.

Exterior cladding mimics natural materials with paneling, shakes or stone accents. Photovoltaic panels, radiant floor heating, smart home technologies integrate seamlessly. Additional finishing includes decorative trim work, fencing, decks and constructed details matching any residential style from modern to rustic.

Luxury fittings throughout including gourmet kitchens, spas, home theaters, carports or entire guest wings expand the structures scope. Ultimately prefabrication streamlines construction while removing no limits in personalized design and quality.

Project Highlight – Sustainable Community

A modern container house development in California exemplifies the scalability and sustainability advantages of modern prefabricated housing communities:

Planners configured 400 identical studio apartments within a 0.5 mile radius utilizing highly insulated modular steel panels. Foundation slabs prepared the 5-acre site. Arriving modules rapidly installed via crane at a rate of 10 units daily.

Photovoltaic roofs generate on-site power shared via smart grids. Rainwater collection and wastewater treatment minimize municipal demands. Electric vehicle charging, bicycle pathways and centralized services reduce individual footprints.

Completed in only 8 months, the energy efficient community provides affordable housing and employment while restoring native landscapes. Its successful replication now supplies shelter for disaster zones globally within days versus temporary tent cities.

Overall this real-world project highlights how planning scaled prefabricated developments streamline construction timelines and costs while prioritizing resident comfort and environmental ethics set new standards for sustainable shelter provisioning worldwide.

Conclusion

Modern prefabricated modular construction has revolutionized building practices, minimizing time and waste to deliver quality, customized shelter anywhere as demanded. Streamlined container house systems leverage engineering and mass-production to establish total housing projects in mere fractions of conventional timelines.

Adherence to detailed construction documents guides assembly with minimal skilled labor. Infinite customization options upgrade structures beyond simple “box” designs. Strategic planning now scales prefabrication towards expansive, self-sustaining communities reconstructed globally as-needed.

Perhaps most remarkably, prefabrication establishes shelter as a rapidly deployable process no longer dictated by location or environment. Standardized modular components override all logistic barriers to shelter establishment. Overall this paradigm fundamentally changes how – and how quickly – societies worldwide can house individuals and groups precisely where and when shelter needs arise.

Related news

-

Prefab House Assembly Detachable Container Construction Site Color Steel Two-Story Dormitory Customization

2024-08-20 17:35:36

-

Feature profiles pilots of Lida Group's scalable prefab panel-home system providing customized housing, classrooms and clinics rapidly installed near shifting communities.

2024-08-19 16:36:01

-

White paper assesses applications of Lida Group's panelized construction for multi-unit transitional settlements integrated with communal facilities using lightweight composite enclosures.

2024-08-19 15:06:26

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com