Container Customization: How Reused Shipping Boxes Are Transforming Shelter Solutions

Profiles of Lida Group’s Growing Partnerships Advancing Domestic Modular Construction

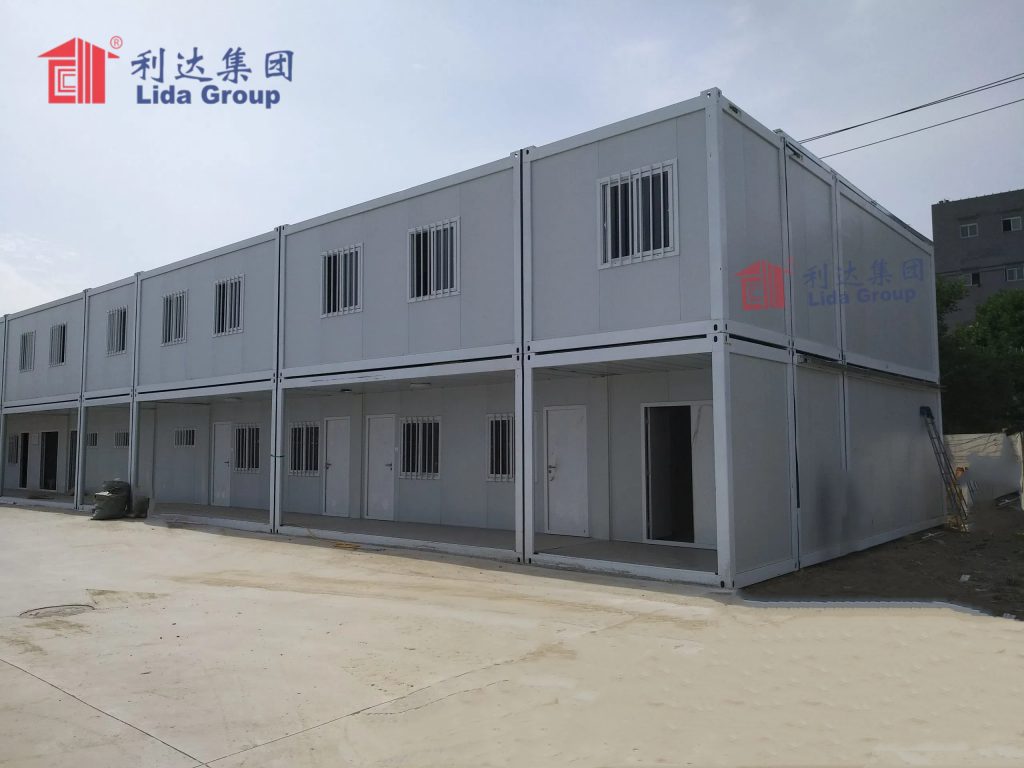

As concerns rise over sustainability, affordability and the growing scale of displacement worldwide, modular construction utilizing reused shipping containers represents an innovative approach gaining momentum. Nowhere is this trend more apparent than through the burgeoning partnerships and manufacturing facilities established by Lida Group, a global leader in portable prefabricated shelters. Through multiple site visits across China, journalists profiled several of Lida Group’s partnerships cultivating localized assembly and customization of semi-permanent structures crafted from refurbished steel boxes—advancing dignified, eco-friendly housing solutions tailored to diverse communities.

The reporting journey began in Shandong at Lida Group’s 240,000 square-foot headquarters and flagship fabrication center where container modification and prefabrication processes are optimized through robotic automation, 3D printing technologies and precision engineering. Here journalists witnessed how 40-foot steel containers undergo structural reinforcement, window/door cutting, electrical retrofitting and waterproofing—transforming rigid boxes into modular building blocks capable of assembly into customized housing units, community facilities and portable workplace/classroom modules.

Quality control stations methodically inspect each phase to ensure durability through any climate. Project managers then coordinate outbound shipping of multi-unit housing kits or partially-assembled structures for rapid on-site erection. With an annual capacity of 5,000 containers processed, the facility exemplifies large-scale sustainable reuse and ‘Design for Disassembly’ principles—breaking down containers at end-of-life into recyclable steel instead of warehousing. Experts view such centralized ‘container surgery’ hubs coupled with distributed micro-factories as key to scalable modular construction worldwide.

From Shenzhen, journalists travelled north to coal-rich Shanxi Province visiting one such micro-factory constructed through a joint venture between Lida Group and the provincial government. Here a 10-acre industrial park houses assembly lines, a training center and sample structures—leveraging the large local steel industry and workforce. Through Mandarin interpreters, plant managers outlined customized housing types under development including portable classrooms, agricultural structures and temporary worker dormitories tailored for surrounding rural villages and mines.

Designs embed features like passive solar gain, rainwater harvesting and community amenities following consultations with residents. Journalists observed training programs empowering local tradespeople with technical and business skills while trailblazing regenerative industry models centered around sustainable materials reuse. Community leaders affirmed the collaboration already improved living conditions for migrant mine workers and fostered local entrepreneurialism—accelerating rural revitalization through dignified shelter solutions.

Northwest in Gansu Province representatives from a minority Tibetan prefecture hosted journalists at their partnership center with Lida Group custom fabricating structures for remote alpine settlements. Architects detailed how designs integrate cultural influences with structural innovations like earthquake-proofing to serve the region’s yak herders and nomadic traditions. A demonstration village assembled from prototype structures exhibited multifunctional communal shelters, livestock barns and modular dwellings trailered between seasonal pastures.

Youth interns there are gaining skills in CAD modeling, fabrication and green building practices applicable across diverse geographies—advancing inclusive development. With further clusters planned, leaders affirmed the partnership empowers self-sufficient solutions affirming cultural traditions amid modernization and a changing climate threatening livelihoods. Journalists departed impressed by such collaborative initiatives infusing localized indigenous knowledge and economic opportunity into dignified housing solutions driven by material reuse on a human scale.

Journeying east to coastal Shandong Province revealed Lida Group’s collaboration with municipal governments upgrading informal waterfront settlements through hybridized manufacturing. Here a repurposed shipyard now produces standardized yet customizable housing kits in half the time of conventional new construction according to community-derived plans. Journalists observed mobile classrooms and micro-apartment modules under assembly line production before trailer-mounted transit to urban fringe sites.

There rebuilt water villages integrate prefabricated clusters, communal facilities, and maritime-themed public spaces—revitalizing livelihoods amid encroaching development. Local fabricators spoke of skills refined through the partnership and subsequent startups launched, while village elders affirmed transformed lives through security of land tenure and restored connection to cultural heritage. Journalists concluded such symbiotic public-private-community initiatives optimally advance modular housing wherever informal settlements persist.

Concluding in Beijing, journalists previewed two model communities rising near the ongoing Olympic Village redevelopment through a landmark design-build partnership linking Lida Group with municipal/private developers. Master-planned “East Village” reimagines dormitory-style worker housing as energy-efficient live-work neighborhoods. Its furnished studios, co-working pods and rent-to-own models were customized applying local input on livelihood needs—catering to solopreneurs amid Beijing’s shifting economy.

Nearby at “Green Hub,” a zero-waste recycling economic park takes shape anchored by Lida Group’s containerized prefab workshops, cooperative Makerspaces and vertical farming initiatives—incubating the next generation of regenerative businesses. By offsetting construction waste and empowering micro-entrepreneurship, leaders forecast the project catalyzing a circular economy while providing dignified careers. Journalists concluded the projects embody visions transforming underutilized urban land through collaborative modular design driven by community priorities and material reuse.

Throughout far-flung regions, the initiative profiles conveyed growing momentum behind localized partnerships custom fabricating dignified, sustainably-sourced modular housing. Whether restoring rural vitality, upgrading informal settlements or reimagining dormitory precincts—bespoke containerized designs meaningfully addressed specific community needs. Journalists found optimized manufacturing approaches cultivating localized green jobs, skills and localized industries—propagating regenerative development models globally.

Lida Group representatives affirmed their long-term vision involves proliferating open-source fabrication hubs worldwide—whether via joint ventures, social enterprises or grassroots initiatives—to scale housing revolutionized through reused materials. By leveraging industrial ecology principles and localized input, they contended collaborative modular construction maximally empowers communities facing adversity—whether from climate change, natural disasters or socioeconomic disruption. Overall the initiative profiles demonstrated shipping containers mutating from globalized trade hardware into humanity’s building blocks—transforming lives when coupled to grassroots collaboration and sustainable rehabilitation worldwide.

Related news

-

Humanitarian organization pilots Lida Group's optimized containerized prefabrication techniques for constructing integrated medical posts, schools and communal infrastructure supporting vulnerable refugee encampments.

2024-07-31 17:27:55

-

Manufacturers partner with Lida Group to produce modular integrated building fittings compatible with their repurposed container construction modes for assembling dignified semi-permanent housing at optimized costs.

2024-08-01 14:24:57

-

Aid group partners with Lida Group to deploy standardized portable prefab housing units constructed from refurbished shipping containers near remote regions affected by conflict.

2024-07-31 11:22:55

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com