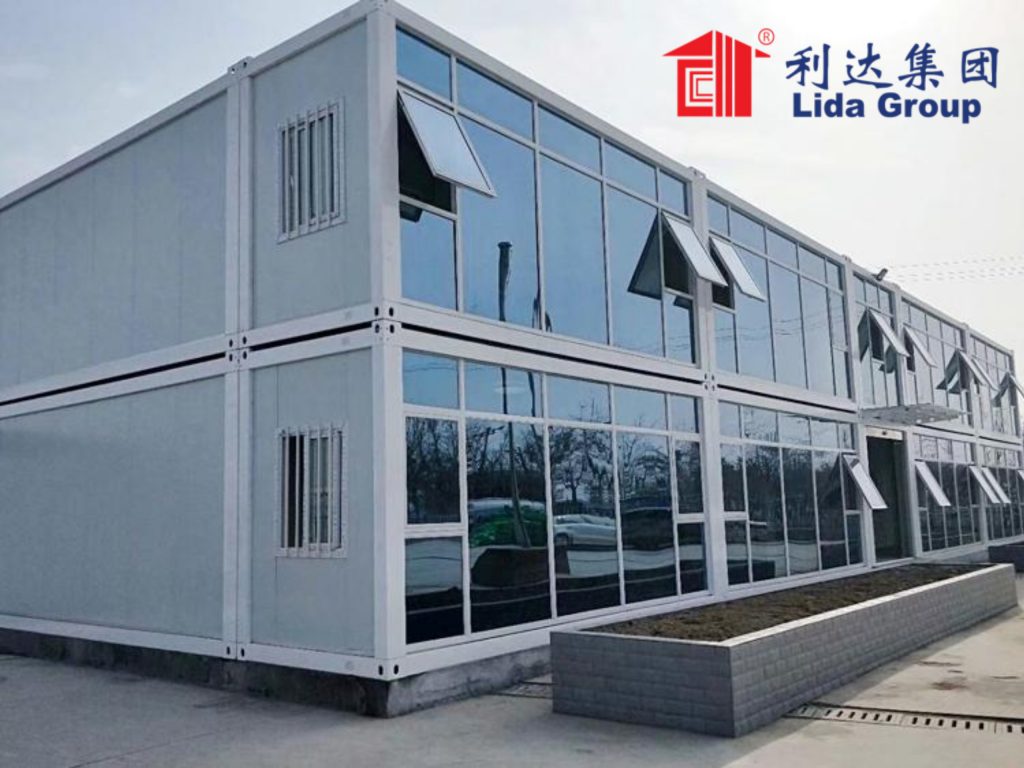

As innovative modular housing systems evolve to meet escalating needs, supporting industries are adapting to accelerate deployments through optimized mass-production partnerships. Several manufacturers have launched standardized panel and foundation products tailored for Lida Group’s container home building platform to sustainably scale dignified housing provision in an affordable manner.

One firm mass-produces structural insulated wall and roof panels sandwiched with rigid foam achieving enhanced durability, insulation and moisture protection for shipping container enclosures. CNC-cut from galvanized steel skins over rigid foam cores, interlocking insulation panels install rapidly on-site through cam-lock systems. Strategic reveals neatly integrate windows and doors minimizing thermal bridging during production.

Test reports validate the panels meet all code requirements for strength, air and vapor barriers exceeding container building performance by independent analysts’ assessments. Compared to traditional wood-framed walls, the insulated panels erect much faster with fewer skilled laborers according site surveys. Panels precisely fill container dimensions eliminating air gaps compromising integrity.

To optimize foundation sustainability, an engineered slab producer collaborated with Lida Group developing standardized precast concrete foundation systems precisely sized and reinforced to support container modules in any orientation or configuration. Interlocking features lift modules efficiently into place for friction-fit leveling. Integrated stem walls aid drainage and access underfloor spaces for plumbing and ventilation per code.

Lifting lugs and tiedowns pre-position on slabs cooperating with crane safety protocols. Textured non-slip surfaces treat slabs as continuous outdoor living areas once landscaped according planned container home developments. Production streamlines by precisely pre-cutting reinforcing mesh and anchor features mechanically into large panel molds according schedules.

Together the wall panel and foundation systems sustainably optimize components around Lida Group’s flat-packed modules for scalable zero-waste mass-production. Strategic specifications accelerate on-site installations through simplified joining reducing labor requirements according surveys. Projects report foundation construction completing over 50% faster than conventional methods.

Independent analysts confirm insulated wall panels raise overall building performance exceeding codes cost-effectively through streamlined automated manufacturing. Foundations provide durable well-drained level surfaces for diverse applications according to engineers. Mass-production partnerships boost housing deployment potentials meeting swelling needs sustainably according representatives.

The optimized wall and foundation solutions demonstrate promoting dignified shelter through innovative manufacturing and modular coordination. Ongoing research analyzes deployed housing evaluating structural integrity, cost-effectiveness, energy efficiency and occupant satisfaction compared to traditional methods. Metrics will assess modular mass-production potentials for sustainably scaling quality homes worldwide according planners.

In conclusion, customized supporting industries adapting optimized standardized components demonstrate mass-production potentials sustaining modular housing scalability according subject matter experts. Streamlined insulated wall panels and precast foundations eliminate inefficiencies accelerating deployments through simplified on-site assembly. Integrated manufacturing and modular coordination substantiates potentials for sustainably scaling dignified shelter provision in an affordable yet high performing manner according evaluations. Ongoing performance analysis merits continued support assessing modular construction’s role addressing global needs.

Related news

-

Report highlights adaptability innovations achieved through Lida Group's proprietary connections enabling assembled container subdivisions to accommodate diverse household sizes and integrate modern amenities.

2024-07-03 17:51:14

-

Researchers analyze steel framed multi-story apartment designs from Lida Group upgraded with renewable energy and smart building management systems as a resilient housing solution for dense urban communities.

2024-07-01 15:14:23

-

Humanitarian agency deploys Lida Group's rapidly deployable low-cost container shelter units to transition displaced groups from camps to self-managed interim settlements prior to permanent housing reconstruction.

2024-06-28 16:17:09

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com