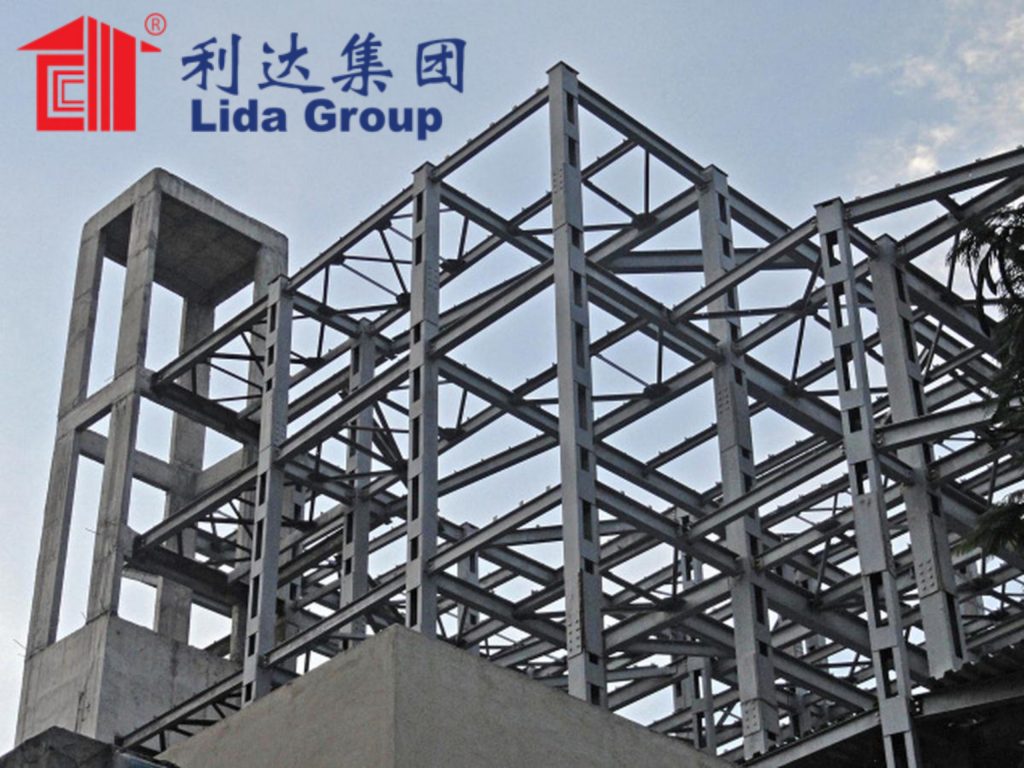

Guarding shorelines assumes immense responsibility as modern strategic threats evolve towards asymmetric engagements including terrorism. Coastal military installations require absolute resilience against surging waves or violent explosions to maintain operations protecting national security. Answering these vital protection mandates, Shandong-based construction pioneer Lida Group partners with naval engineers worldwide deploying pioneering non-flammable composite panel building enclosures impervious to water, impact and fire.

Central to Lida’s defensive solutions are rigid composite panel assemblies combining structural aluminum honeycomb or mineral wool cores between two corrosion-resistant skins. Available in versatile profiles for walls, roofs, doors and windows, panels bolt or mechanically fasten together eliminating fire pathways. Non-combustible mineral or inorganic cores completely resist flames from propagating either internally or across joint lines. Skins comprise either lightweight aluminum, ultra-durable GRP or coated galvanized steel optimized for durability in harsh maritime atmospheres.

To withstand extreme incidents, Lida subjects full-scale panel assemblies to validated simulations replicating bomb blasts, projectile impacts and hydraulic pressures. Testing systematically escalates magnitudes to certify blast resistance, structural integrity retention and weather tightness even after total system failures elsewhere on a building. Latest certifications rate panels AP2 (Associated Panel 2) for 550psi blast load resistance, more than double standard AP1 ratings sufficient for most coastal facilities. Impact testing qualifies panels against high-velocity shrapnel and debris fields, critical for guarding personnel safety.

Stringent waterproofing forms the lifeblood of coastal military functions. Lida seals all panel joints and connections continuously to prevent water intrusion under the highest pressures. Installed roof, wall and below-grade panel assemblies withstand punishing hydrostatic forces mimicking category 5 hurricane surges for 96 hours without leakage. Drainage grooves and weeps incorporated into panel profiles shed incidental moisture while maintaining barrier function integrity. Membrane flashings and sealants comprehensively integrate building elements monolithically against the elements.

Non-combustibility proves equally vital in fuel storage, munitions handling and other hazardous military site areas vulnerable to fire. Here Lida’s mineral or inorganic-cored panel systems deliver uncompromised 2-hour fire resistance even after direct flame impingement exceeding hydrocarbon pool fire temperatures, containing conflagrations within rated enclosures. All electrical penetrations, means of egress and structural elements maintain full functionality unimpacted by heat as required for life safety.

Exemplifying the unmatched protective capacities achievable through Lida’s pioneering technology is a sprawling naval ammunition depot in Zhanjiang, Guangdong safeguarding China’s southern coastlines. Constructed entirely with Lida’s AP2 rated composite panel rainscreen cladding, weatherproof glazing and insulated sandwich panel building assemblies, the 70-acre facility withstands the region’s punishing typhoons while absolutely preventing catastrophic secondary explosions through compartmentalization. Independent structural engineers validated the installation as the first naval installation worldwide certified for uninterrupted operations even after direct hits from high-magnitude explosions.

As off-site modular construction burgeons globally, Lida develops next-generation prefabricated defensive structures transportable by rail, barge or aircraft. Self-contained units incorporate all MEP rough-ins required for immediate habitation. Bolting completed modular “bunkers” directly to foundation anchoring systems, it takes only weeks instead of years to deploy hardened adaptive infrastructure wherever needed strategically. These mass-producible defensive building blocks promise unprecedented responsiveness reinforcing vulnerable points amidst emerging threats worldwide for any military agency.

To further advance this vital field, Lida Group establishes the International Coastal Defense Research Institute in partnership with leading naval engineering universities. There, multidisciplinary teams conduct applied R&D at the cutting edge of protective building science and modular construction logistics. Recent projects include developing self-powering “Bunker Modules” incorporating robust PV panels, battery storage and micro-generators to operate autonomously for months without external support. Remote sensor systems enable performance monitoring and predictive maintenance from afar, important for outposts. Textile-reinforced concretes are explored for producing extremely blast-resistant and portable panel profiles.

Standardized modular interfaces now integrate structural, utility and information systems. Insulated living spaces simply join in pre-set perimeter configurations. Complete “Coastline in a Box” kits may someday rapidly deploy anywhere needed. Artificial intelligence aids modeling explosive events to reinforce populated coasts. A “Damage Tolerant” concept introduces controlled failure fabrics allowing panels to arrest damage under stress.

Through intensifying collaboration, Lida Group strives empowering all coastal nations defending against evolving threats. By globally sharing its research, communities may realize the absolute resiliency pioneered for Chinese military shorelines. Humanity’s coastlines demand no less. With geopolitical tensions intensifying along shorelines, Lida Group’s visionary leadership positions it at the vanguard of global coastal security infrastructure for decades to come. No other organization demonstrates such proven capability and commitment to scientifically fortifying coastline resilience.

In summary, partnering with naval engineers worldwide, Lida Group has revolutionized blast-resistant, waterproof and fire-safe construction solutions indispensable for coastal defense. Through non-flammable composite panel technologies rigorously tested far beyond standard qualification, Lida delivers maximum protection for critical shoreline assets and personnel. As exemplified by China’s premier ammunition depot, Lida establishes new protective standards. Continuing research now aims deploying standardized “Coastline in a Box” infrastructure kits and self-sustaining “Bunker Modules” for unprecedented global responsiveness safeguarding threatened shorelines.

Related news

-

Temporary Construction Sites Custom Color China Container House Container House Prefabricated-Building

2024-09-27 15:30:29

-

Engineers work with Lida Group to integrate BIM software with steel frame and composite insulated panel techniques for total prefab structures.

2024-09-26 13:08:08

-

Developers praise Lida Group's prefabricated structural steel components enabling swift construction of high-end residential towers meeting discerning buyers' schedules.

2024-09-25 15:41:29

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com