Introduction

Prefabricated container homes have grown in popularity due to many advantages over traditional building methods. Known as prefab container houses, these unique modular homes are constructed using standard shipping containers as the primary building material. Crews stack, bolt or weld containers together to form complete living spaces optimized for functionality and comfort. While similar in principle to conventionally built houses, container homes bring intrinsic characteristics from their origins in global freight transport.

History of Shipping Containers

The concept of adapting cargo containers for dwellings arose after World War 2. Steel containers revolutionized worldwide trade but left many discarded at journey’s end. In 1958, architect Colin Davie built one of the first units attaching framing to a repurposed container in Hong Kong. Interest grew slowly as container living gained feasibility demonstrations worldwide. However, prefab container homes only gained momentum following the late 2000s recession when falling housing availability made containers an affordable housing alternative. Developers recognized containers’ durability could provide post-industrial modular building blocks. By reducing costs versus traditional construction, prefab container homes addressed an important need.

Advantages of Prefab Container Homes

Affordability

Used shipping containers have low acquisition costs since transportation operations discard them once useful lives end. Less labor, materials and time are required for assembly than conventional framing. Total prices range from $40,000-$150,000 depending on size, lower than comparable traditionally built residences.

Sustainability

Prefab homes promote reuse through repurposing durable steel shipping containers. Compared to newly manufactured building materials, containers demand fewer wood and composite products while generating less construction waste. Their wall insulation requirements also decrease. Modularity enables simple expansions or relocations.

Rapid Assembly

Standard container dimensions ease prefabrication of components assembled quickly on-site. Foundations and module connections take longest. With plans prepared in advance, assembly often finishes 1-3 months versus 6-18 months for standard builds, reducing carrying costs.

Durability

Shipping containers endure years of global transportation stresses. Their double-walled construction provides rugged fortification against natural disasters when securely anchored to foundations. Post-disaster resilience enhances longevity.

Customizability

Creatively configured multiple container units allow infinite floorplan options. Personalized features provide visual interest balancing industrial origins affordably. Options suit diverse preferences.

Potential Limitations

Container dimensions confine living spaces requiring optimization. Additional insulation improves thermal performance beyond basic shells. Resales remain relatively untested though advantages are increasing popularity as green building alternatives.

Prefab Container Home Types

Single Container Cabins

Self-contained accommodation in one compact enclosed box, often as studios or backyard cottages.

Linear Home Layouts

Multiple end-joined long containers form smooth multi-room corridor designs for narrow infill lots.

L-Shaped and U-Shaped Configurations

Attached at right angles or around courtyards to include outdoor space without compromising interior square footage.

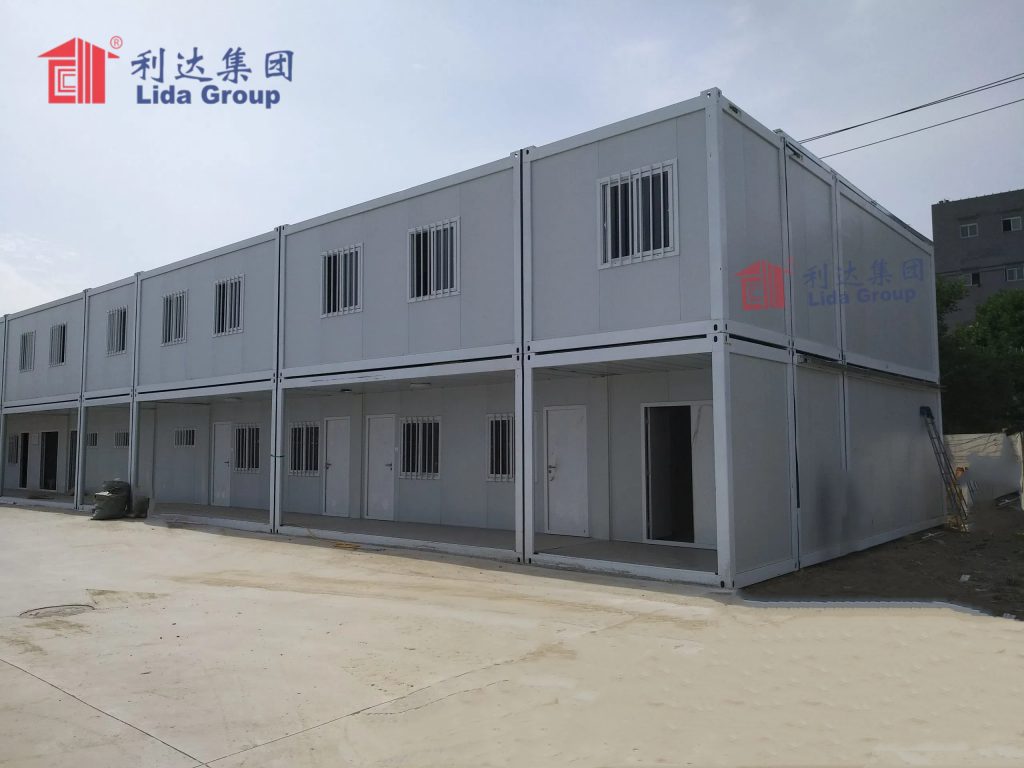

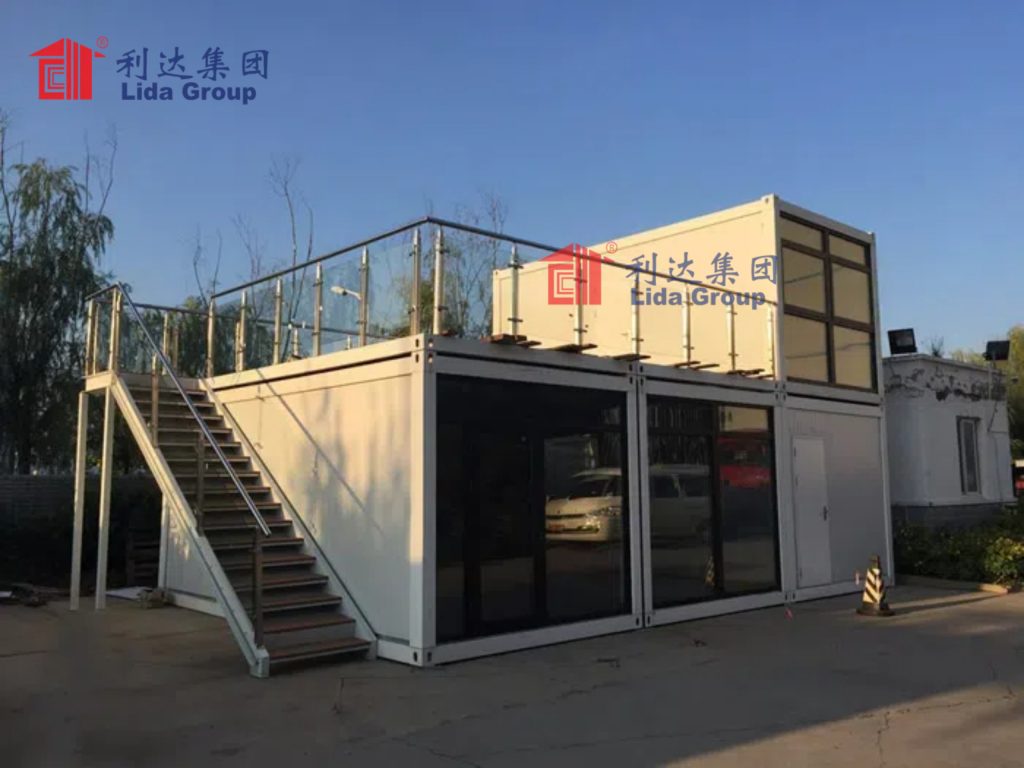

Two Story Structures

Stacking doubles living area through versatile upper and lower container levels connected internally.

Tiny Homes

Minimal 20-40ft containers adapted for micro-living seeking hassle-free ownership.

Communal Housing

Groupings like courtyard clusters provide co-living benefits within a private residential compound.

Expandable Layouts

Modular starters enable incremental growth matching family lifecycles through progressive container additions.

Farmstead Homes

Spreading arrangements resemble old agricultural structures through gabled roofs and staggered heights.

Modernist Styles

Emphasis on clean lines, large windows and geometric connections exude contemporary character.

Luxury Custom Designs

High-end features and materials lend estate-like qualities to sustainably fabricated structures.

Prefab Container Home Features

Floorplans optimize tight dimensions:

Open Layouts

Removed drywall maintains flow between unified living areas.

Built-In Furniture

Wall units and sleeper sofas recover floor space inconspicuously.

Multi-Functionality

Dedicated office/studio niches maintain privacy without sacrificing room.

Full Kitchens Fittings

Clever base cabinetry disguises appliances compactly.

Storage Solutions

Sliding shelves and pocket cabinetry fully leverage vertical inches.

Compact Bathrooms

Skylights and compact fixtures maintain comfort within small footprints.

Extended Indoor-Outdoor Zones

Terraces blur the boundary with covered decks opening living space.

Prefab Container Home Construction

A standardized process fast-tracks assembly:

Site Preparation

Leveling and compacting gravel subgrades support loaded containers.

Foundations Installation

Pouring reinforced pads or pilings anchors each secured module.

Container Placement

Mobile cranes precisely position modules before sealing joins.

Interior Framing

Subflooring and wall framing accommodate mechanics and finishes.

Window/Door Installation

Prefabricated glazing optimizes airflow and illumination.

Exterior Finishing

Siding and roofing complete the visual envelope.

Insulation and Air Sealing

Encapsulating interiors establishes an efficient thermal barrier.

Interior Finishing

Installing fixtures positions homes for occupancy.

Inspections and Certification

Sign-offs authorize inhabitation once compliant.

Prefabrication in climate-controlled factories ensures high quality control. Connecting pre-assembled components on foundations permits rapid on-site erection. Modular prefab container homes provide sustainable housing solutions using repurposed industrial materials for adaptable designs accommodating diverse lifestyles. As populations increase, container construction shows promise for affordable future construction.

Conclusion

Prefab container homes deliver numerous benefits over traditional residential building processes. Their modular assembly leveraging standardized containers as pre-cut components allows economical, expedited construction with minimized negative environmental impacts. Sustainably repurposing durable shipping infrastructure, prefab container houses provide affordable, customizable living spaces that perform efficiently through optimized building science details. As vacant containers accumulate globally, innovative construction methods play an important role in housing shortfalls. With permeant foundations securing against natural disasters, prefab container structures demonstrate housing alternatives benefiting diverse demographics presently and for generations to come. As design and execution improve with industry experience, modular construction holds promise for sustainable shelter needs across various markets.

Related news

-

Engineers collaborate with Lida Group to develop multi-storey steel framed apartment prototypes utilizing insulated sandwich panelized systems for simplified off-site manufacturing.

2024-09-26 16:16:30

-

Government allocates funding for Lida Group to produce disaster resilient prefabricated housing incorporating galvanized steel substructures and reinforced sandwich exterior walls.

2024-09-26 13:19:51

-

Lida Group steel framed big-box retail and industrial developments lauded for flexibility to modify interior layouts without disruption to hasten tenant move-ins.

2024-09-25 14:25:02

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com