Introduction

The modern prefabricated home industry has seen rapid evolution in recent decades as sustainable and accessible housing solutions gain widespread popularity. A cutting-edge trendsetter amongst these innovations has become the versatile prefab container home. Constructed from standard shipping containers, these dwellings maximize footprint efficiency while delivering unmatched durability.

Let’s explore the myriad advantages spurring massive growth within the prefab container home construction sector. Qualities around affordability, transportability and rapid deployment make these builds especially attractive to homeowners, developers and off-grid communities seeking shelters tailored for modern lifestyles.

Materials and Design

At the core, prefab container homes craft living spaces from typical steel intermodal containers used worldwide for cargo transportation. Ranging 8-10ft in width by 40ft lengths, their corrugated metal shells intrinsically deliver robust superstructures ready to uphold walls, floors and roofs.

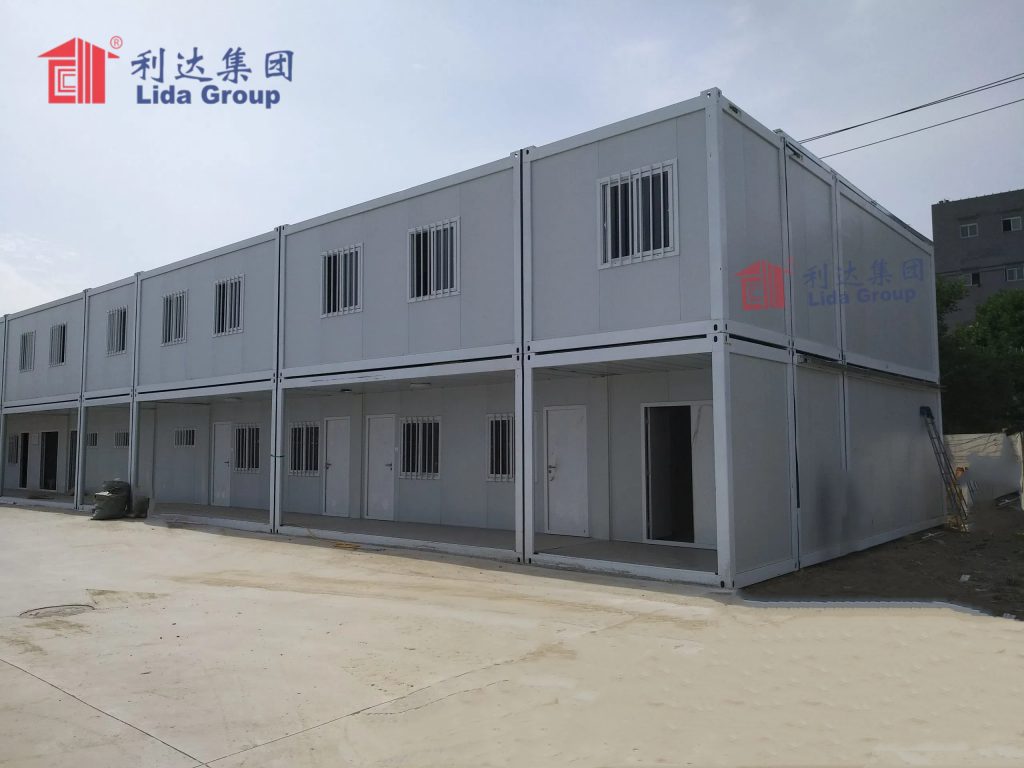

Containers stack either vertically or side-by-side to form the skeleton around which interior systems integrate. Prefabricated elements such as bathroom pods, wardrobe units and appliances finalize each room off-site under controlled conditions. Wiring, plumbing and fixtures fully preinstall for fast on-location completion.

Insulated composite wall and roof panels then envelop the steel frames for superior environment control. Factory fitted windows, doors and electric systems complete watertight weatherproof exterior shells that arrive ready to inhabit. These modular sections interconnect on foundations through standardized corner brackets.

An open floorplan concept allows endless layouts by shifting preconstructed sections. Additional floors stack simply by coupling containers vertically. Through their interchangable compositional design, container homes accommodate changing needs of growing families or downsizing seniors with flexibility.

Transportability

A core advantage sees entire prefab homes smoothly transported as completed units rather than scattered building materials. Standard shipping containers grant trouble-free worldwide freight mobility via ships, trains and trucks on established infrastructure.

Remote locations previously inaccessible due to terrain suddenly gain housing options as prefabs move in via single deliveries. No foundation construction required beforehand and simpler installations lower costs. Crews connect pre-outfitted pods with basic hand-tools.

Should owners later relocate, disassembly takes a single crane to separate compartments for re-shipping. Piece by piece reassembly mirrors the first process. Some flexibility even allows remodeling interior partitions without dismantling existing containers.

This unprecedented portability opens new opportunities for temporary project sites, crisis relief camps, overseas expatriate housing or ultra mobile tiny houses still attached to nature’s beauty everywhere on the globe. Boundaries for living bloom infinitely broader.

Sustainability

From inception, container homes center around sustainability without compromise to durability, aesthetics or functionality. Their steel shells endure harsh climates for centuries while maintaining 100% recyclability at life ends.

No wasting materials occurs during precise prefabbing as advanced as aerospace engineering to maximize yields. Reduced transport packaging waste results from consolidated moved-in units versus scattered components. Resource inputs fall through reuse of post-industrial containers otherwise sent to scrap.

Thermal bridging minimizes thanks to preinstalled interior wall sheathing. Superior insulation and airtight construction lower utility expenses over entire lifecycles compared to traditional builds absorbing more solar heat gains each summer.

Controlled indoor preassembly avoids wasteful on-site leftovers and improves working conditions for laborers. At project completions, recyclable components give contractors circular product options. These eco-friendly advantages clearly position containers as homes of the future.

Cost Effectiveness

Cost savings realize through value optimization starting from repurposing waste cargo metal into structural raw material. Modularization streamlines labor with parts constructed independently then snapped together time efficiently by small installation teams.

Reduced building periods shrink interest rates on financing. Lower insurance premiums arise from noncombustible steel construction fireproof materials. Owners gain from economical operations having spent minimal funds on conditioning enclosed spaces naturally daylit by ample windows.

Prefabrication economies scale production using advanced computerized cutting and prewiring techniques. Bulk purchasing collective container orders further lowers per unit costs passed directly to buyers. All combined, prefab containers undercut estimates for comparable traditional stick construction by 15-30% commonly.

Resale values retain strength as designs continuously customize to new owner needs while maintaining structural soundness through exceptional multi-generational lifespans. Long term ROI rewards those capitalizing on future-proofed prefab sustainability.

Customization

While capitalizing on prefabricated efficiencies, continuous customizations allow personal expression. Multi-color palettes and varied siding options upgrade exteriors visually. Interior layouts divide freely as homes comprise independent reconfigurable pods.

High-end fittings and features accommodate luxury lifestyle desires. Solar arrays or greenhouse additions expand usable spaces creatively. Floating decks and landscaping bring the indoors outside in harmony with nature. Multiple units arrange cooperatively as unique sustainable neighborhoods.

Creative recycling repurposes other post-industrial containers into imaginative ancillary structures on the same properties. Community spaces could house workshops, shared offices or guest residences. Aesthetic exteriors showcase prefab technology with high design rather than boxlike appearances historically associated.

Individual homeowners control their designs with architects and even DIY modifications. Commercial projects attract investors through customizable multi-unit complexes, dormitories or mixed-use developments. Options essentially place dreams in reach for any budget through prefabricated quality.

Applications

Certainly prefab container homes gain traction as adorable tiny living abodes or eco-cabins. However, scaled-up applications unlock greater population housing. Affordable apartments and condominiums efficiently span multiple containers arranged around shared spaces.

Remotely powered villages settle previously inaccessible natural locations through off-grid autonomous infrastructure. Manufactured home communities rebuild neighborhoods rapidly at low cost after disasters. Governments tap potential solving mass shortages in developing nations.

Businesses acquire temporary or even permanent relocatable offices, clinics, schools and stores through customized prefabs. Various container repurposing sparks artist studios, café patios and micro-retail concepts. End uses seem limitless with creativity.

Sustained growth appears inevitable as container homes address critical world issues through accessible, transportable and impact-minimized housing. Their combinable modularity efficiently maximizes spaces within cities or liberates living beyond traditional infrastructure. Infinite scaling transitions prefab technology from niche to ubiquitous.

Prefab Market Growth

As advantages accumulate recognition, prefab container home construction flourishes continually. North America leads early worldwide adoption amid housing shortages and costs crisis. Europe transitions from caravans and tiny prefabs towards permanent container settlements.

Developing Asian and African markets spike demand by implementing region-specific designs through local collaboration. Mass prefab housing programs soon address substandard slums in megacities. Australia pioneers off-grid habitable stations within extreme desert and ocean environments.

Prefab specialists emerge offering turnkey packaged designs coordinated through intuitive online configurators. Standardized component sizes decrease costs attracting mass retailers expanding availability. Surging interests push technological enhancements towards self-sufficient net zero designs.

Access to simple construction loans primes new homeowners previously priced out. Government incentives promote sustainable prefab communities’ revitalization. Projected growth suggests prefab market value tripling within a decade as container homes gain widespread acceptance across all continents.

Conclusion

In summary, the rise of prefabricated container home construction represents the natural evolution of housing towards maximized sustainability, mobility and customization. By leveraging existing post-industrial resources through modular designs, these builds achieve unmatched footprint and transportation efficiency without compromising quality or aesthetics.

Superior durability, affordability and resilience against natural disasters has seen remarkable uptake in many nations facing pressing shortages and infrastructure challenges. As technologies continue improving and scaling up through entire master-planned communities, the prefab container home revolutionizes worldwide concepts of shelter design. With benefits enabling all demographics universal access, prefabs are undoubtedly housing the future.

Related news

-

New Design Prefab Foldable House Steel Structure Durable Building Commercial Flak Pack Container House

2024-10-10 17:29:07

-

Temporary Construction Sites Custom Color China Container House Container House Prefabricated-Building

2024-09-27 15:30:29

-

Prefabrication experts at Lida Group integrate quality steel frame construction into efficient design-build process for medical office parks and mixed-use complexes.

2024-09-25 15:15:43

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com