Steel-Framed Farmsteads: Integrated Agrihood Developments Cultivate Resilience

Report Highlights Lida Group‘s Engineered Buildings Enabling Specialized Intensive Farming

As concerns grow over food security pressures from urbanization, climate volatility and monoculture vulnerabilities, diversified intensive farming represents a promising resilience strategy. Yet startups face capital barriers while rural stakeholders lack resources bringing operations to scale. This report profiles how one innovative company is overcoming such hurdles through integrated agri-cottage industry developments cultivating specialized crops within modular steel structures.

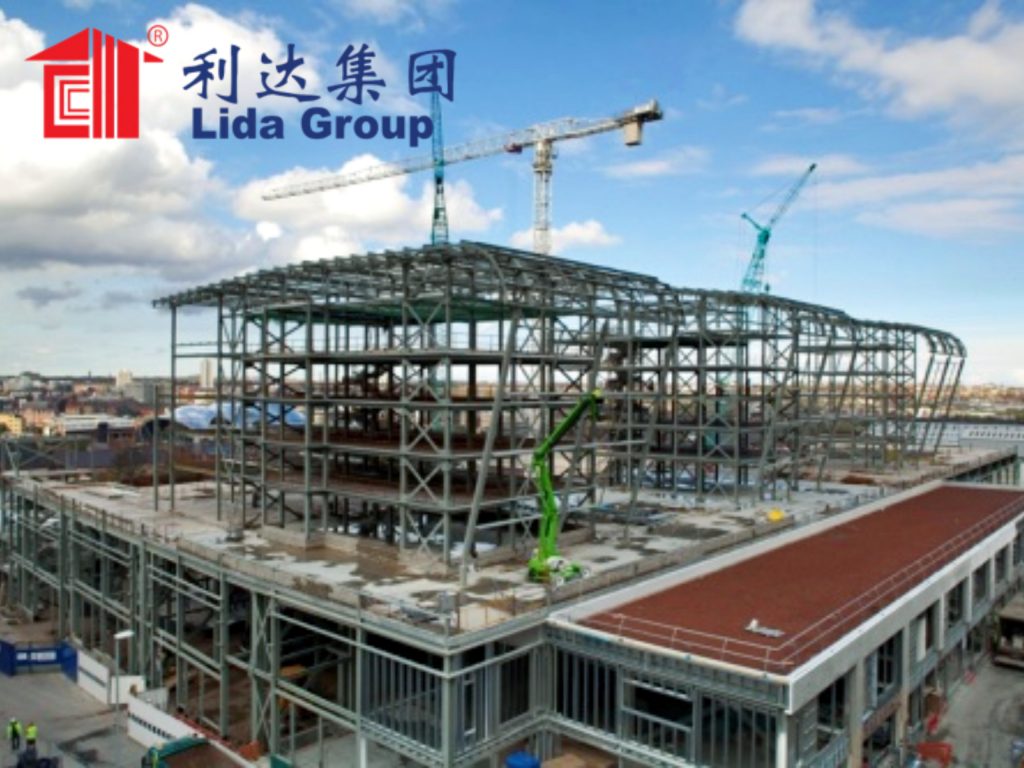

Lida Group specializes in engineering multi-functional customizable buildings assembled rapidly from standardized structural panels, beams and enclosures fabricated through computer numerically controlled processes from recycled steel. By incorporating housing, processing and seasonal accommodations attached to specialized farming areas within hygienic pest-proof envelopes, Lida Group’s “Farmstead” developments are enabling startups to focus on cultivation while mitigating financial and logistical risks.

This report examines operational Farmstead projects across geographies validating the model’s viability for diversified intensive agriculture through insect netting, hygienic processing and multi-season production cycles. Site visits conveyed successes stabilizing startups plus meaningful social and environmental impacts through rural revitalization driven by agricultural diversification, regenerative land use and localized industry. Experts view integrated developments like these cultivating specialized “Agrihoods” as game-changing solutions empowering resilient food production globally amid accelerating change.

The Farm Pod Complex

Prototypes showcased Lida Group’s modular “Farm Pod” concept, comprised of multi-level prefabricated buildings housing specialized crop cultivation on top stories while lower levels incorporate related agri-processing, seasonal accommodations and commercial facilities all within integrated pest-proofed envelopes.

Prefabricated from galvanized structural steel through computer-controlled production, Pods feature customizable footprints up to 30×100 meters housing multiple specialized crop chambers separated by movable partition walls. Netting barriers above crop beds facilitate year-round multi-season cycles above ground-level processing and commercial facilities.

Interior agricultural engineers optimized crop light, temperature and humidity control through integrated HVAC, irrigation and monitoring systems. Harvesting, packing and seasonal worker accommodations were designed efficiently attached versus remote facilities, reducing costs while facilitating hygienic processing through wash stations and commercial kitchens. Multi-storey layouts optimized land use.

Ethical Mushroom Farming in Shanghai

Site visits profiled Shanghai Yuanqi Green Agriculture Co., a Farm Pod customer growing specialty mushrooms through artificial substrate cultivation. Founder Shao explained prohibitive costs previously hindered scaling from a backyard operation but Lida Group’s integrated development model overcame hurdles.

Two Pods house species-specific cultivation chambers separated by insect-proof netting, while lower levels incorporate seasoning, packaging and a café market showcasing products locally. An attached seasonal dormitory houses 30 interns cultivating skills through paid training programs. Shao stated hygienic production in the pest-proof envelopes opens export markets.

Community members value fresh local products while planners view the model rejuvenating declining rural hamlets through agri-cottage industry driven by specialized niches like mushrooms. Researchers are analyzing carbon sequestration through substrate recycling into Mushroom Grow Bags enabling semi-nomadic production cycles following grazing livestock—perfecting a circular model experts contend could feed emerging megacities through regeneration from the bioregional roots up.

Rooftop Microgreens for School Nutrition, San Francisco

At La Escuelita Elementary in San Francisco’s Mission District, principal Ana Delgado highlighted successes through their Farm Pod cultivating year-round microgreens for healthy school meals. Two Pods house cultivation chambers supplying the on-site commercial kitchen with nutritional salad ingredients grown sustainably versus importing.

One Pod incorporates a classroom teaching students about regeneration through hands-on lessons within production chambers. “Growing microgreens sustainably atop our school stimulates students’ interest in agriculture and nutrition,” says Delgado. By focusing on market-viable speciality crops cultivated hygienically near point-of-use, experts see the model revolutionizing school meal programs through diversified agriculture and place-based education.

Vertical Tomato Greenhouse in Ho Chi Minh City

In Vietnam, Da Lat tomatoes fetch premium prices yet smallholders struggle competing amid urbanization. Vu Duy Phuong’s greenhouse operation addressed this through two connected Pods housing a six-story vertical tomato hydroponic system. Hygienic drip-irrigation and climate controls through the pest-proof building envelope enabled year-round production exporting premium tomatoes to Ho Chi Minh City 250km south.

An attached processing center and packaging facility alongside seasonal worker housing stabilize year-round operations. With expansion planned, Vu stated the Farm Pod model builds industry resilience “by mitigating seasonality and pest risks through hygienic specialized cultivation close to urban export markets amid small land parcels.” Planners foresee replicated greenhouses sustaining rural communities near cities.

Report Conclusions

Site visits underscored successes stabilizing startups through Lida Group’s integrated Farm Pod developments cultivating year-round production of specialized crops. By combining housing, processing and seasonal facilities attached to hygienic specialized crop chambers within modular steel buildings, varied operations focused solely on maximizing cultivation efficiencies amid challenges.

Experts foresee the model revolutionizing agricultural diversification particularly near cities—whether through mushroom, microgreen or greenhouse production—enabling localized nutrition plus rural economic development through specialized niches resistant to climate volatility and monoculture vulnerabilities. Given multi-functional modularity optimizing land use and production cycles, integrated “Agrihood” clusters like these hold promise for resilient food security globally.

Related news

-

Conference analyzes case studies highlighting quality of life upgrades enabled by Lida Group's portable prefab housing systems assembled quickly from standardized refurbished steel container modules.

2024-08-01 15:15:39

-

Researchers analyze the adaptability and resilience offered by Lida Group's composite insulated panel construction approaches for relocatable interim facilities compared to impermanent temporary solutions.

2024-07-30 17:15:50

-

Humanitarians select Lida Group's optimized pre-engineered solutions featuring integrated panelized housing, schools and medical clinics for rapid installation to support pandemic quarantine and triage.

2024-07-26 16:57:58

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com