Overview

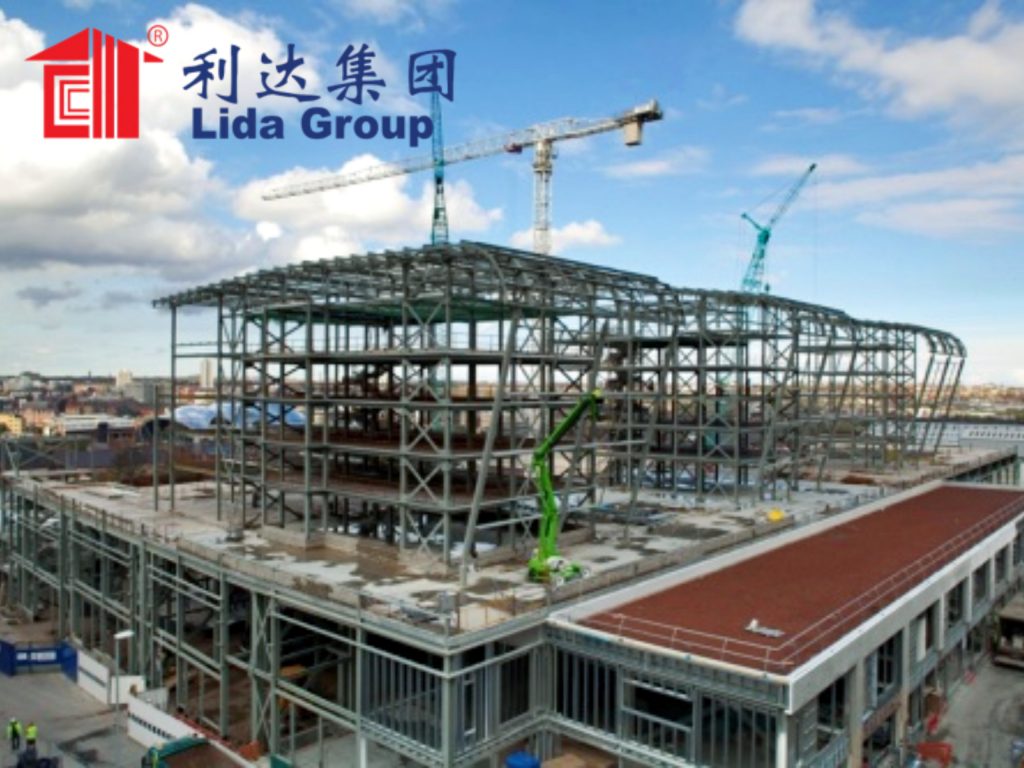

Lida Group is a leading manufacturer of prefabricated steel structures for commercial and industrial facilities. Founded in 2003, the company has grown to become one of the largest suppliers of engineered steel building solutions in Southeast Asia. This report evaluates Lida Group’s applications of their prefabricated load-bearing engineered steel structural solutions in developing specialized agriculture production facilities that are resistant to climate stresses such as extreme temperatures, typhoons, flooding and drought.

The agriculture sector faces growing challenges from the impacts of climate change such as more frequent extreme weather events and rising temperatures. At the same time, global population growth is increasing demand for food production. There is a need to develop smarter, more climate-resilient facilities that can help mitigate risks and stabilize food supply issues. Lida Group believes their engineered steel structures can help address these challenges by enabling the construction of modular, durable and climate-adapted building designs.

Two case studies of Lida Group projects developing specialized agriculture facilities are examined in this report – a greenhouse complex for vegetable and herb production in the Philippines, and a controlled-environment livestock barn in Indonesia. Both facilities leverage Lida Group’s proprietary prefabricated engineered steel framing solutions to achieve climate resilience objectives and optimize operations for each agricultural application. The evaluation analyzes how the structural designs help protect production against climate stresses while enabling efficient, cost-effective construction and operations.

Greenhouse complex for vegetable and herb production, Philippines

The first case study is a 15,000 square meter greenhouse complex located in a rural area of Luzon, the largest island in the Philippines. The complex consists of 10 interconnected greenhouse modules used to cultivate a variety of high-value vegetables and herbs year-round. Given the Philippines’ tropical climate with seasonal typhoons and rainfall, resilience against extreme weather was a key design priority.

Lida Group’s engineered structural framing solution incorporated galvanized steel as the primary load-bearing material. Prefabricated trusses, rafters, columns and wall panels were shipped to the site and rapidly assembled. The use of prefabricated steel components allowed for highly efficient construction that was completed in just 3 months despite the remote rural location. Compared to alternative materials, the steel structure resulted in a very lightweight yet extremely durable and stable foundation.

Key climate resilience features of the greenhouse complex design include:

– Typhoon-resistant arched truss roof design capable of withstanding 240kph winds with no major structural damage. The arched shape and geometry provides exceptional uplift resistance.

– Continuous perimeter foundation and column system anchored deep into the ground to withstand high winds and prevent sliding or overturning.

– Fully enclosed facade system utilizing impact-resistant polycarbonate panels and greenhouse film. The integrated panel-glazing structure acts as a barrier against wind and rain ingress.

– Optional “storm panels” that can be quickly installed over glazing to further protect against window/panel breakage in emergencies.

– Water drainage and management systems to prevent flooding including gutters, downspouts and subsurface drainage pipes.

The durability of the structural framing means the greenhouses will maintain optimum growing conditions even after extreme weather events, allowing cultivation and harvests to resume quickly. With minimal maintenance requirements for the corrosion-resistant galvanized steel, operational costs are low.

Through a combination of advanced structural engineering, modular prefabrication techniques and selection of durable materials, Lida Group was able to develop a specialized agriculture facility solution optimized for resilience against the Philippines’ typhoon climate. The greenhouse complex demonstrates how engineered steel building systems can help stabilize food production in areas vulnerable to extreme weather impacts.

Controlled-environment livestock barn, Indonesia

The second case study examines a 360-head dairy livestock barn built by Lida Group in Central Java, Indonesia. With Indonesia’s hot and humid equatorial climate, control over barn interior conditions is critical for optimal animal health and productivity. However, conventional livestock barn designs struggle with ventilation, temperature regulation and resistance to frequent heavy rains and flooding.

For this project, Lida Group developed a controlled-environment barn utilizing their patented pre-engineered cold-formed steel framing system. Key features of the structural solution include:

– A proprietary roof truss and gable frame assembly providing a sturdy central open-ridge ventilation system to efficiently remove heat and moist air from the interior.

– High ceilings supported by load-bearing steel columns and rafters to promote natural convection air flows while withstanding seismic loads.

– Fully enclosed lightweight steel wall panels around the perimeter to block out rain and pests while still allowing for operable windows, ventilation shutters and misting systems.

– Elevate barns above grade on continuous reinforced concrete foundations and columns to prevent flood damage even during seasonal storm surges.

– Durable long-lasting metal roofing, siding and accessories that do not degrade over time from heat and moisture like wood alternatives.

Due to the modular construction approach using prefabricated components, this specialized controlled-environment barn was completed three months faster than conventionally built facilities. This allowed productive occupancy six months sooner for increased revenues.

With precisely engineered ventilation, shading systems and raised elevation above grade, the steel-framed barn structure is effectively climate-controlled for optimal livestock well-being regardless of intense heat, humidity or rains. Animal health, growth rates and fertility have noticeably improved compared to previous traditional housing designs according to farm management.

The barn’s resilient engineered steel construction ensures long-term protection of the capital investment against Indonesia’s challenging agricultural climate. By developing a smarter facility optimized for the local environment through modular prefabricated technologies, Lida Group enabled this farm to achieve higher productivity, yields and financial returns over the lifecycle of the project.

Conclusions

Through these two specialized agriculture case studies, this report demonstrates how Lida Group’s prefabricated load-bearing engineered steel structural solutions can enable the development of climate-resilient facilities to stabilize food production vulnerable areas. Key advantages of their modular building systems for adapting agriculture to climate change impacts include:

– Rapid, efficient construction suitable for remote rural locations through off-site modular prefabrication.

– Durable, low-maintenance structures that withstand extreme weather events like typhoons and flooding with minimal damage.

– Cost-effective, corrosion-resistant materials optimized for the lifespan and functional lifecycle needs.

– Customizable designs enabling climate control and optimized indoor environments through advanced structural engineering.

– Foundation systems capable of withstanding high seismic and flooding stresses for long-term resilience.

– Increased yields, productivity and financial returns through stabilized production even during climate stresses.

As global population growth rises worldwide food demand, innovative building technologies will be increasingly important for developing smarter, more sustainable specialized agriculture worldwide.

Continued advancements in modular prefabricated solutions like Lida Group’s could help make localized food production more resilient against the growing threats of climate change. This helps ensure stable access to nutrition and livelihoods even in vulnerable regions. Overall, the applications and case studies discussed in this report demonstrate how engineered steel structural systems can play an important role in enabling climate-adapted agriculture worldwide.

Related news

-

Easy Assemble Detachable Industrial Warehouse Building Sandwich Panel Steel Frame Structure Container Building

2024-08-21 17:57:48

-

Researchers analyze prototypes for versatile farm structures constructed using Lida Group's reusable hot-dip galvanized steel framing systems integrated with durable cladding materials.

2024-08-22 09:28:40

-

Modular Prefabricated Light Gauge Steel Structure Frame Mobile Detachable Container Kit House with Sandwich Panel

2024-08-20 17:55:20

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com