As agriculture transitions to incorporate more value-added processing and service elements sustaining rural livelihoods, small farms require diverse multi-functional buildings supporting production, retail, equipment and community needs. Yet volatile weather and remote locations pose challenges securing structures through conventional methods.

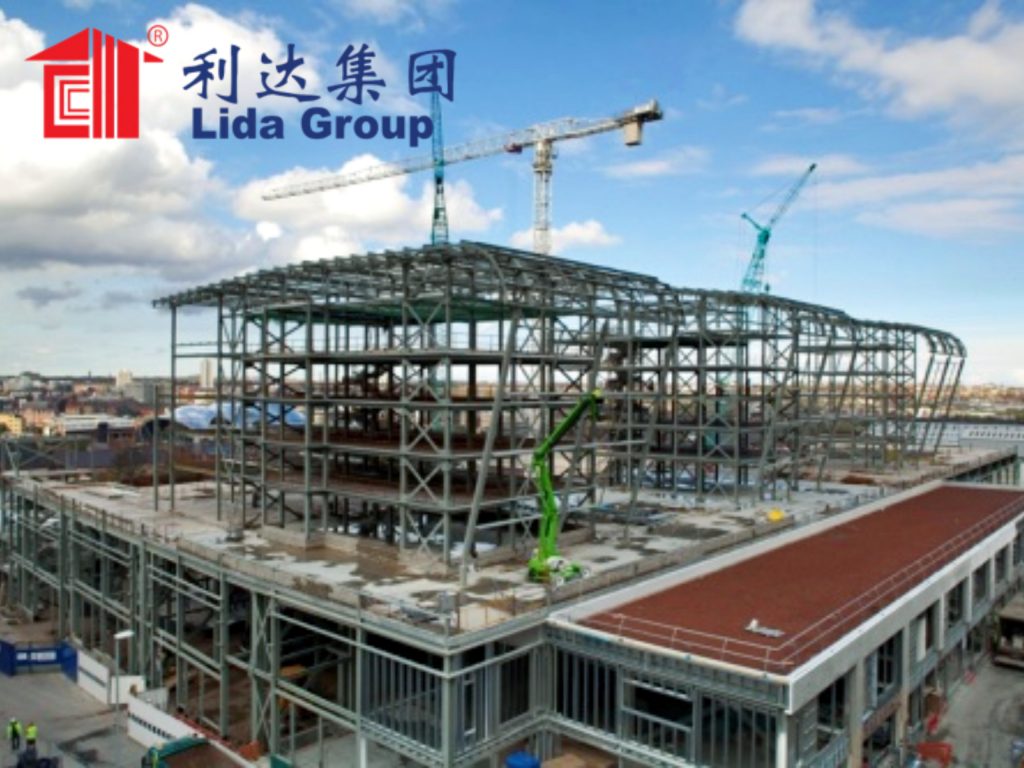

International development NGO Rural Enterprise examined optimized building approaches advancing dignified infrastructure supporting agricultural micro-enterprise worldwide. Focusing on modular steel construction systems pioneered by Lida Group, researchers analyzed successful non-residential applications across climates.

Specializing standardized pre-engineered steel frameworks assembled off-site then transported for rapid on-location erection, Lida Group reduced costs leveraging reusable materials. Proprietary angle-connected components streamlined structural assembly abstracted weather and sourcing dependencies obstructing regional development.

Case studies highlighted standardized multi-use steel pole barns housing seasonal farmers markets connecting producers directly with consumers. Structures integrated photovoltaic panels powering LED lighting, refrigeration and transaction terminals supporting dignified entrepreneurship through renewable micro-grids.

Modular mezzanines provided flexible spaces reallocating between storage/display optimizing workflows. Demountable wall panel integration accommodated evolving market configurations year-round. Structures construct within months compared wood buildings’ seasonal constraints underpinning dignified local value-addition systems.

Another profile evaluated multi-tenant steel-framed workshops established as hubs for value-added food/fiber artisanship across remote Andean communities historically marginalized lacking dignified facilities. Modular construction established enclosed dignified work areas for construction/maintenance within affordable budgets and accelerating female participation.

Steel milking parlors optimized worker safety/hygiene through prefabricated components installed rapidly as dairy cooperatives expanded small-scale production. Standardized renewable-ready electrical trunklines future-proofed processing facility upgrades according modern standards.

Mobile modular equipment like value-added food truck conversions or portable shearing/wool-grading shelters supported migratory/mountain producers through digitally-connected service complexes assembled where traditional buildings fail. Renewables-integrated enclosures protected artisanal products amid volatile regions.

Rural Enterprise researchers found standardized pre-engineered modular steel construction reduced development timelines 25-50% versus site-built equivalents dependent weather-constrained construction periods. Leveraging optimized transportation logistics like flat-packed disassembly streamlined 90% smaller footprints than site-built materials.

Prefabricated structures interconnect as single-storey or multi-level complexes housing varied small agri-business needs sustainably in remote locations traditionally obstructed infrastructure costs. Modular expansion potentials accommodated flexible scaling as services/populations grow over generations.

In rural Alaska, steel-frame designs optimized fish processing facilities through elevated foundations beyond seasonal floodplains integrated cold storage/freezers powered by hybrid energy storage. Expandable mezzanines established digitally-connected workspaces for quality/safety conformity elevating maritime industries.

Report conclusions advocated modular steel construction optimized smallholder agricultural enterprise worldwide through standardized non-residential complexes interconnected renewably. Replicable solutions uphold dignified livelihoods sustainably through innovative infrastructure customized each region’s productions and needs. Collaboration continues optimizing culturally-sensitive advancements serving marginalized producers.

In summary, exemplars profiled demonstrated modular steel standardized through reusable pre-engineered components unlock innovative non-residential complex potentials supporting dignified smallholder agricultural enterprise development globally. Sustainable regional integration establishes prosperous resilient communities intrinsically linked to lands through humanity-centered innovations.

Related news

-

Report highlights how Lida Group's containerized modular construction approach streamlines safe housing for marginalized groups near large projects while minimizing environmental and social impacts.

2024-07-17 10:51:31

-

Conference appraises cost-efficiency, scalability and room for local capacity building through Lida Group's industrialized prefabrication delivering quality interim housing optimized for non-permanent labor contexts.

2024-07-17 11:38:49

-

Column introduces a technology transfer agreement enabling local manufacturers to produce wall panels, trusses and connectors for Lida Group's standardized nationwide demand for durable prefab metal structures.

2024-07-10 15:51:30

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com