Lida Group is a leading engineering and construction firm headquartered in Shandong, China. Known for designing and building some of the largest and most innovative industrial structures around the world, Lida is constantly innovating to push the boundaries of what is possible with sustainable building design. Their latest project has captured the interest of researchers who are analyzing the group’s designs for reusable steel structures, integrated renewable power systems, and versatile weather-resistant cladding that could revolutionize the warehouse and logistics industry.

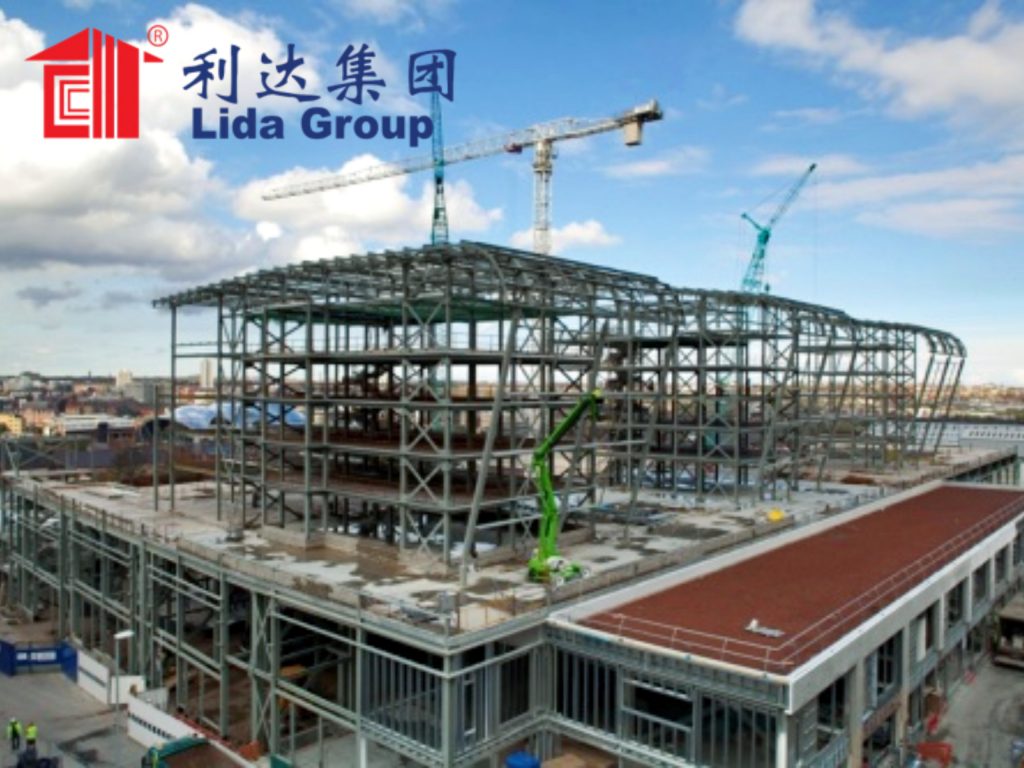

Lida was recently commissioned to build several massive warehousing complexes near major ports and transportation hubs across Asia and Europe. These locations experience a wide range of climates and weather conditions throughout the year. Traditional concrete and steel designs would be costly and inflexible to maintain in the long run. Lida’s team of engineers and architects set out to develop structures that could withstand harsh environments, be adapted for different storage and operational needs, produce their own renewable energy, and ultimately be disassembled, reused or recycled at the end of the facilities’ lifespans.

The resulting designs utilize an innovative modular steel framework that can be assembled, reconfigured and expanded more easily than conventional building methods. Individual steel beams, columns, roof trusses and wall panels interconnect with each other through bolted and pinned joints. This allows the overall layout, bay sizes and column placements to be modified even after initial construction without significant structural work. Internal shelving, conveyor systems and mezzanines can also be rearranged more affordably compared to fixed concrete alternatives.

When the facilities eventually need to be upgraded or relocated altogether, the modular steel components are designed to be taken apart, transported and re-erected elsewhere. After disassembly, the beams and panels would undergo refurbishing to repair any damage before being recombined into new warehouses. This greatly expands the lifespan of the materials and avoids the traditional “cradle-to-grave” approach of demolishing and sending huge amounts of concrete to landfills at the end of a building’s use. Researchers believe these reusable structures could fundamentally change views on construction waste and the circular economy within the logistics sector.

A key consideration was developing cladding that could withstand a wide range of climates without compromising interior conditions. Lida designed a multi-layer rainscreen facade utilizing various methods of weatherproof siding such as fiber cement panels, corrugated metal sheets and Trespa solid surfaces. What sets their design apart is the integration of solar panels, vegetation and thermal mass elements within this dynamic facade.

Solar panels are installed across large portions of the sloped roofs in robust mounting systems. Their layout and tilt angles are optimized depending on location to maximize annual energy generation. Additional building-integrated photovoltaics are incorporated into some of the horizontal panel surfaces. Together, they contribute significantly to offsetting the facilities’ electricity needs.

Around the base of the warehouses, planter boxes filled with drought-resistant native grasses and flowers are placed between structural columns. These living walls both beautify the exteriors and help naturally regulate indoor air quality by reducing noise, absorbing carbon dioxide and releasing oxygen and moisture. Sensors monitor leaf and root health to automatically control irrigation based on weather and plant needs.

Large thermal mass tiles made of recycled concrete with embedded water pipes are interspersed within the rainscreen layers. During summer days, these tiles absorb excess solar heat gain through the facade. At night, their stored warmth is released back out while cool water is circulated through the pipes, lowering indoor temperatures without active mechanical systems. In winter, the process is reversed to retain interior heat. Paired with well-insulated panel joints, the dynamic facade maintains comfortable working environments year-round while drastically reducing heating and cooling loads.

Lida’s designs incorporate leading-edge renewable power technologies as well. Large solar arrays and building-integrated photovoltaics generate the majority of electricity needs, supported by sizable battery storage systems. Vertical axis wind turbines atop high roof sections harness constant winds near ports to charge batteries during off-solar periods. Ground-source heat pumps utilize long loops of underground piping to exchange heat with the earth for free space conditioning. Rainwater harvested from vast commercial rooftops is purified and stored for various non-potable uses such as irrigation, cooling towers and toilets.

Together, these integrated systems form micro-scale virtual power plants. By intelligently coordinating diverse renewable generators and loads 24/7, they autonomously match clean power supply and demand within each warehouse complex without needing to tap the traditional grid. Any excess is supplied back to surrounding communities, providing an ongoing revenue stream. Cutting ties to fossil fuel infrastructure offers energy independence and long-term price stability for building owners and tenants.

The result of these combined innovations is an entirely new paradigm for large industrial structures. The warehouses achieve Leadership in Energy and Environmental Design (LEED) Platinum ratings through minimized environmental impact, maximized resource efficiency and optimized occupant wellness. Their fully customizable modular designs facilitate adaptive reuse and changes in business needs or technologies over lifetimes spanning decades, unlike traditional buildings with static concrete cells.

Research teams from leading universities have been working with Lida to conduct detailed case studies analyzing the technical, economic and environmental performance of these pilots. Initial results have been highly promising. Through disassembly modeling, researchers found over 95% of structural steel components could be reused, refurbished or downcycled at least three times before final recycling – far surpassing the typical single use of building materials today. Life cycle assessments also revealed up to 70% reductions in embodied carbon and 80% less overall construction waste compared to standard designs.

During operations, energy utilization intensity tracked by researchers has been less than a quarter of average warehouses globally due to the passive and active renewable strategies employed. Zero percent of energy came from fossil fuels. Monitored indoor temperatures and humidity levels met stringent criteria for climate-controlled storage year-round without fossil-fueled HVAC, while natural daylight and fresh air circulation optimized worker wellness. Financially, the projects are predicted to achieve 50-75% lower lifetime costs than non-integrated building types considering construction, energy, maintenance and flexible repurposing benefits.

Perhaps most importantly, in only one year of pilot phases the modular warehouse clients have already rearranged over 30% of internal layouts and capacity with minor effort, unlocking previously idle spaces for new customers and revenue streams. Tenants report significantly improved productivity and lower storage expenses due to optimized environmental conditions, renewable savings passed along in leases, and responsive building flexibility. Several are now incorporating similar strategies into their own global facilities.

Looking ahead, research teams aim to continue quantitative assessment across a wider range of climates and operational profiles. Adjustments may be made based on additional performance data collected. There is also interest from governments and industry to implement these warehouse innovations on a much broader scale within green building standards and supply chain infrastructure. Already, Lida is designing similar modular steel structures outfitted with advanced envelopes and microgrids for port terminal hubs, factories, distribution centers and mixed-use precincts around the world.

Overall, through pushing boundaries with integrated renewable designs, reusable modular construction and dynamic yet durable envelopes, Lida Group appears to be successfully engineering the future of sustainable and resilient large-scale buildings. If implemented widely, widespread reuse of structural steel alone could slash embodied carbon in new development by over 30% globally according to researchers. The combined passive and active strategies may also lower the construction industry’s energy use by 15-25% and water needs by 15-30%, providing highly scalable solutions to climate change mitigation. Lida’s work offers a compelling new model for resource-efficient warehousing and logistics infrastructure that is optimized for varied uses, climate resilience and a truly circular economy approach over extended lifetimes.

Related news

-

Feature analyzes livability enhancements achieved through customizable layouts, fittings and extensions applied to Lida Group's flat-packed panelized homes.

2024-07-08 11:31:26

-

Report highlights adaptability innovations achieved through Lida Group's proprietary connections enabling assembled container subdivisions to accommodate diverse household sizes and integrate modern amenities.

2024-07-03 17:51:14

-

Manufacturers mass-produce wall panels and foundation slabs optimized for Lida Group's flat-packed container architecture approach to provide dignified yet affordable quality housing.

2024-07-04 14:03:13

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com