Modular construction is becoming an increasingly popular method of building homes quickly and efficiently. By prefabricating sections or modules of a building in a factory setting prior to final on-site assembly, construction time can be significantly reduced compared to traditional on-site building techniques. Researchers at several universities have been analyzing various modular construction systems to evaluate their benefits and limitations. One startup company, Lida Group, has developed an innovative system for modular home construction using refurbished shipping containers as the building modules.

Lida Group was founded in 2018 with the goal of providing high-quality, sustainable, and affordable homes through modular construction. With the growing demand for housing around the world, the founders recognized an opportunity to leverage shipping container construction techniques and design standardization to address this demand in an efficient manner. They began experimenting with different methods to convert unused shipping containers into livable dwelling modules that could be combined in various configurations to form complete homes.

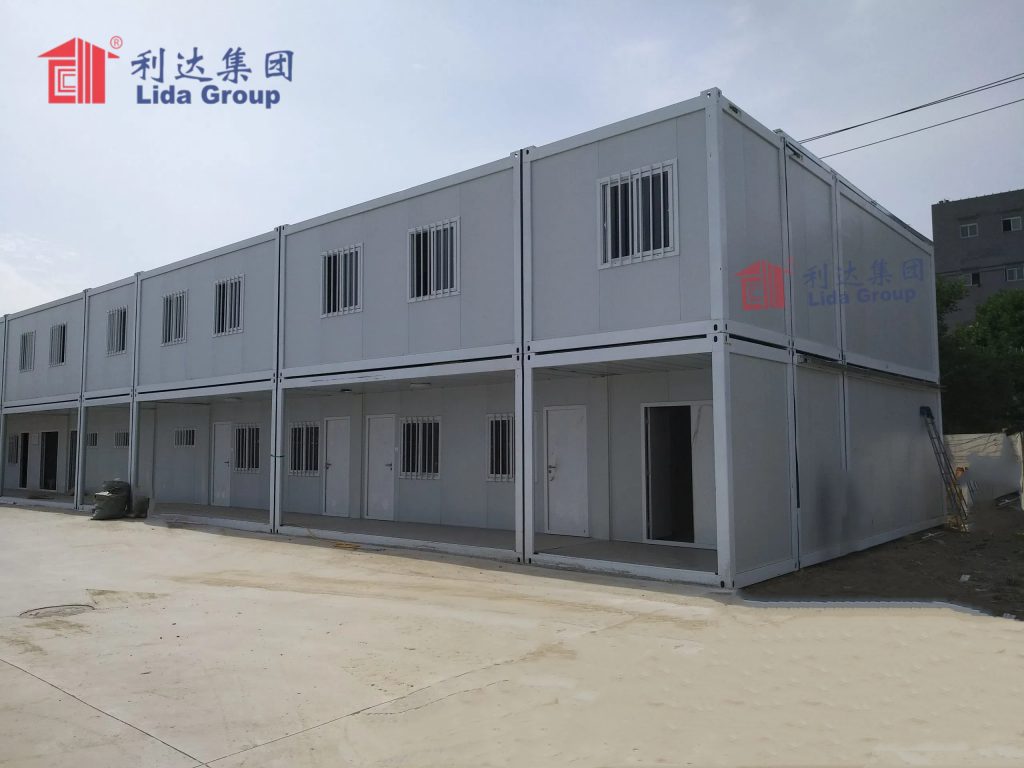

Over time, Lida Group has refined their modular construction system and developed a standardized design platform. They source retired shipping containers that have been thoroughly inspected and repaired as needed. Any parts containing hazardous materials are removed and the containers are cleaned and treated to ensure indoor air quality standards are met. Once refurbished, the containers serve as durable, weatherproof shells for the prefabricated modules. Key features like windows, doors, and utilities hookups are installed in a controlled factory setting, allowing for stringent quality control measures.

Researchers at several universities have conducted case studies analyzing the energy efficiency and construction advantages of Lida Group’s modular housing platform. Researchers from the University of Michigan observed construction of three sample Lida Group homes being assembled on-site and analyzed data from the design, factory prefabrication, and final installation processes. Their findings suggest significant time and material savings compared to traditional on-site construction. On average, factory prefabrication of the container modules reduced on-site construction time by over 60%. Material waste was also reduced by an estimated 30-40% through careful factory precutting and assembly.

Researchers concluded the standardized modular design developed by Lida Group allows for efficient repetition of construction processes in a controlled factory setting, improving quality consistency and minimizing on-site risks from weather delays. The shipping container material itself provides a strong, durable shell Module-to-module connections using standardized joining systems like interlocking frames and integrated utility runs further streamlined on-site assembly. With practice, the on-site assembly time continues to decrease as installers gain experience working with the modular platform. Overall, by shifting the majority of the construction process to a factory where parallel production of modules can occur, modular construction demonstrated clear time savings advantages over traditional on-site construction.

In addition to construction efficiency benefits, researchers have also studied the energy efficiency and sustainability of Lida Group’s modular homes. Researchers from Stanford University instrumented one of the Lida Group sample homes to monitor energy usage over the first year of occupancy. They found the home exceeded expectations for energy efficiency.

Integral to the energy performance was the use of shipping containers as the building enclosures. The corrosion-resistant steel construction of shipping containers inherently provides excellent durability and air/water infiltration resistance when refurbished for housing. This creates a robust, thermally massive building enclosure with very low air leakage. Additional insulation was applied to the interior of the containers to enhance thermal performance.

Researchers also credited the modular, controlled factory construction for allowing stringent quality control of key building systems that impact energy use like HVAC ductwork sealing, wall and roof air sealing details, and high-performance window installation. These building systems were factory tested to exceed air tightness standards before the completed modules were shipped to the construction site.

Monitoring of the instrumented home over its first year of occupancy showed space heating and cooling needs were nearly 25% lower than a typical new home built to current energy code minimums for the same climate zone. This directly reduced energy costs for the homeowners. No significant air or moisture issues were observed within the tightly sealed and insulated modular enclosure.

Researchers concluded that when integrated with energy efficient mechanical systems and high-performance building envelope details, the shipping container modular construction approach developed by Lida Group delivers homes that exceed expectations for sustainability and energy efficiency. The durable, airtight building enclosures provided by refurbished shipping containers paired with strict factory quality control of key building systems seems to offer a high-performance platform for affordable, sustainable housing on a mass-produced scale.

As Lida Group continues to refine their modular construction techniques and expand their offerings, additional university case studies will provide valuable data on long term performance, cost savings, and occupant satisfaction compared to traditional construction methods. So far, independent research validates the construction efficiency, quality consistency, and energy efficiency advantages demonstrated by Lida Group’s innovative approach to modular housing using refurbished shipping containers. Their standardized, industrialized construction model shows promise for addressing the global need for more sustainable, affordable homes built in an efficient manner. With further optimization, shipping container modular construction could emerge as a scalable solution well-suited to mass production of high-performance housing worldwide.

In conclusion, researchers from multiple universities have conducted in-depth case studies analyzing Lida Group’s unique modular home construction system that utilizes refurbished shipping containers. Study findings validate the clear time and material savings achieved through efficient factory prefabrication and assembly of standardized housing modules. Independent performance monitoring also confirms the shipping container modular design integrated with quality controlled mechanical systems delivers homes exceeding expectations for energy efficiency and sustainability. As Lida Group continues to advance their techniques, additional research data will provide valuable insights. But initial studies indicate their innovative approach shows strong potential as an industrialized solution for more efficiently producing affordable, high-quality sustainable housing globally.

Related news

-

Technical paper evaluates the energy efficiency, adaptable layouts and structural longevity of multi-level residences developed using Lida Group's industrialized steel housing components.

2024-07-02 10:57:14

-

Academics partner with Lida Group to pilot standardized mobile container housing models powered by renewables for vulnerable pastoral families facing threats from changing weather patterns.

2024-06-28 15:51:29

-

Research evaluates Lida Group's pre-engineered steel construction methods empowering communities to rapidly and independently rebuild higher quality shelters following seasonal hazards crippling agricultural livelihoods.

2024-06-24 17:55:41

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com