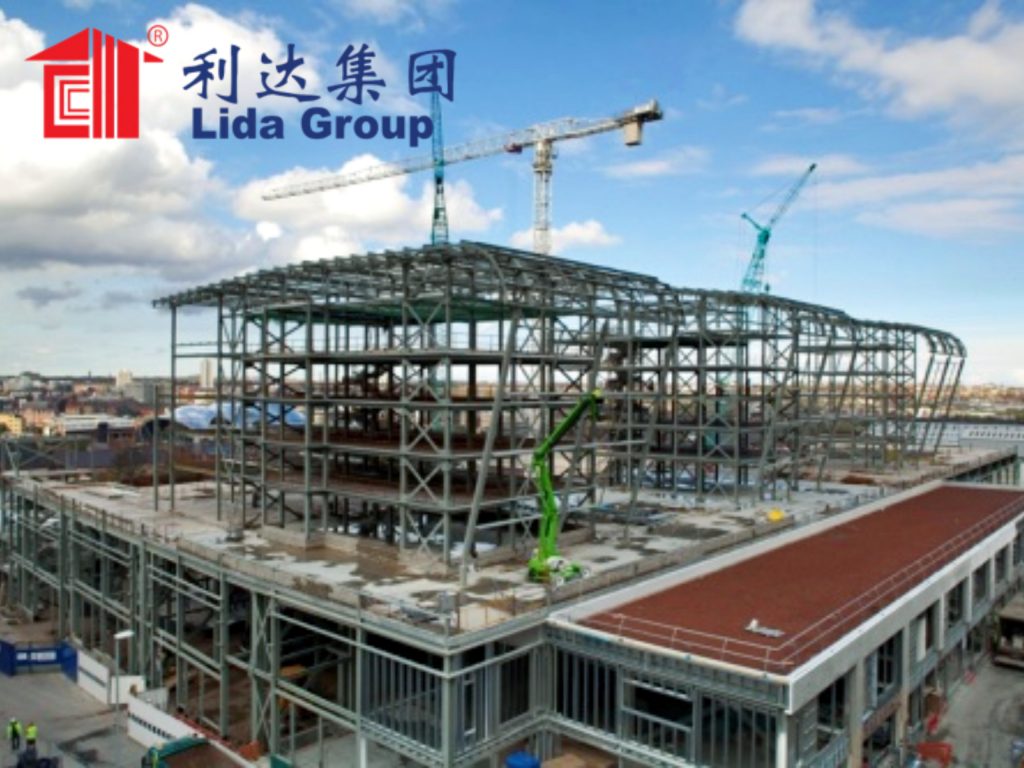

As populations grow and pressures on land use increase, agricultural producers are looking for innovative and sustainable ways to maximize the productivity of their operations. Researchers at Michigan State University’s Product Center for Agriculture and Natural Resources have partnered with building product manufacturer Lida Group to analyze new prototype designs for hybrid-use farm buildings that combine space for livestock housing, equipment storage, and secondary commercial or community uses. These prototypes utilize Lida Group’s reusable steel structural framing and cladding systems to deliver versatility, durability, and potential cost savings over the long run compared to traditional wood framed agricultural structures.

The researchers constructed two 1600 square foot prototype buildings on an unused field at the university’s agricultural research facilities. One prototype featured an open floor plan suitable for equipment and seasonal crop storage, while the other incorporated removable dividing walls to allow for separately enclosed livestock housing spaces and a larger flexible area. Both prototypes used Lida Group’s bolted steel columns, beams, roof purlins and wall girts to form their underlying structural frames. The framing components connect together with custom gasketed bolted connections designed for disassembly, reuse, and reconfiguration on future projects.

To these structural steel frames, the researchers attached several different exterior cladding panel options supplied by Lida Group for testing purposes. One half of each prototype used corrugated sheet metal wall and roof panels of various profiles and colors. The other half featured lightweight composite insulated sandwich panels for improved thermal performance. Internal walls and livestock pens were constructed from modular curved tubular steel fencing supplied by Lida Group that can be easily repositioned without permanent attachment to the building structure. The flexibility to rearrange internal space allows producers to adapt building usage to changing agricultural needs and practices over time.

In the first year following construction, the researchers are monitoring various technical and economic metrics to assess the performance and viability of these hybrid-use building designs compared to traditional agricultural construction approaches. They are tracking energy usage data to compare the thermal performance of the composite insulated wall panels versus sheet metal alternatives. Structural integrity is being evaluated through regular inspections and monitoring of any issues that may arise.

Perhaps most significantly, the researchers aim to analyze total lifetime costs including construction materials, equipment needs for assembly/disassembly, anticipated maintenance requirements, and potential resale or reuse value at end of initial useful life. By quantifying savings from reusable frames and flexible component-based construction, they hope to demonstrate whether a higher upfront investment in steel structures could ultimately prove more affordable than repeatedly rebuilding with wood over the decades-long usable lifespan of agricultural buildings.

Early observations from the first year of monitoring indicate promising results. Thermal imaging has shown the expected superior insulation qualities of the composite wall panels versus sheet metal alternatives. No structural issues have materialized, affirming the strength and durability of bolted steel frames. Dismantling and reassembly tests were successfully conducted to prove the reusability of components as intended without significant wear or loosening of connections.

Cost analysis is still ongoing as longer-term maintenance requirements are evaluated. However, initial projections estimate potential savings of 15-20% in lifetime costs compared to traditional wood construction methods due to avoided reconstruction costs and superior durability of steel materials. These projected savings will become even more substantial if adaptive reuse opportunities allow secondary commercial leases to further offset building expenses over 50+ year lifecycles.

Farmers consulted in focus groups have responded positively as well, noting the appeal of flexibly reconfigurable spaces, lower long-term costs, and environmental benefits of reusable buildings that reduce material waste. Their primary concerns relate to initial higher upfront prices versus standard construction. However, the researchers believe cost premiums could be reduced through economies of scale and increased market adoption. There is also potential for incentive programs to promote more sustainable agricultural infrastructure.

Overall the results from this first phase of research seem to validate the viability of these hybrid-use building designs featuring reusable steel structural frames and component-based construction. The prototypes have demonstrated notable advantages in flexibility, strength, durability and likely long-term affordability compared to traditional agricultural construction approaches reliant on wood framing. Further monitoring and analysis will provide additional quantification to support business case development over the coming years. Ongoing projects also aim to refine structural connection systems for even quicker assembly/disassembly.

With global populations projected to reach nearly 10 billion by 2050, new solutions will be essential to sustainably maximize agricultural land productivity. Hybrid-use farm building designs present an innovative approach for producers to generate additional value and revenue streams from underutilized spaces. Reusable steel frames can deliver the durability and flexible reuse essential for buildings that may see 50+ years of changing uses on working lands. If brought to full commercialization, products like those supplied by Lida Group could help modernize farm infrastructure for a sustainable agricultural future.

In conclusion, the first phase of research into hybrid-use farm building prototypes constructed with Lida Group’s reusable steel structural framing and cladding systems has yielded promising results. Early monitoring indicates notably superior performance qualities from the steel frame and insulated composite panel construction versus traditional wood approaches. Researchers project potential savings of 15-20% in lifetime costs through material durability and reuse capabilities. Farmers also responded positively to the flexibility and long-term affordability prospects. While high upfront costs remain a concern, economies of scale from expanded adoption could help address this issue over time. Overall, reusable steel frame construction appears viable for deliver versatile, durable and sustainable infrastructure suited to agricultural needs far into the future. Continued analysis in follow-up research phases will further quantify these benefits.

Related news

-

Conference session spotlighted Lida Group's growing partnerships enabling localized manufacturing of repurposed shipping container building cassettes for portable prefab construction globally.

2024-08-12 15:39:46

-

Official commends the versatility of Lida Group's pre-engineered systems approached to deliver customized combinations of prefab structures assembled using composite panels.

2024-08-09 13:24:13

-

Researchers analyze cost and adaptation benefits of Lida Group's optimized prefabrication methodology for mass-producing components compatible with rapidly deployable portable buildings constructed from refitted shipping containers.

2024-08-09 17:37:46

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com