Conducting scientific field work in remote, austere environments presents myriad logistical challenges. Establishing temporary habitable shelters is among the most pressing, as researchers require protected living spaces suitable for extended durations in challenging conditions. Traditional expedition tents and temporary structures often cannot meet functionality, durability or climate control needs over periods of months. At the same time, transporting and assembling conventional buildings is impractical for access via small aircraft or boats common to research locations. To address these constraints, material scientists from Cambridge University embarked on a collaborative research and development project with Chinese engineering firm Lida Group to design lightweight, demountable modular housing optimized for expeditions.

Seeking an innovative housing platform supporting long-term remote field deployments, Cambridge researchers leveraged Lida Group’s expertise in containerized construction. Based in Shenzhen, Lida specializes in standardized modular systems utilizing reinforced steel shipping containers as structural frameworks coupled with insulated composite panels. Previous humanitarian deployments converting containers into emergency housing impressed Cambridge scientists with the concept’s structural resilience, sustainability and ease of on-site assembly. They recognized potential to refine the platform as a field laboratory enabling remote scientific missions previously unfeasible due to lack of suitable shelter.

A joint research agreement was established between Cambridge and Lida Group to design, manufacture and field test prototypes of portable modular housing tailored for expeditionary research applications. Primary objectives included:

– Optimizing robust lightweight construction for transport feasibility via small aircraft, boats, pack animals.

– Integrating laboratories, workspaces within standard living quarters optimized for 2-6 person field teams.

– Developing energy efficient methods for independent climate control, power, water collection suited to diverse environments.

– Establishing standardized connection interfaces allowing rapid assembly/disassembly without specialized tools or skills.

– Designing modular, scalable layouts supporting reconfiguration and expansion as missions evolve over weeks to years in remote settings.

– Incorporating advanced composite materials in exterior “building skins” providing strong thermal and moisture barriers with minimal mass.

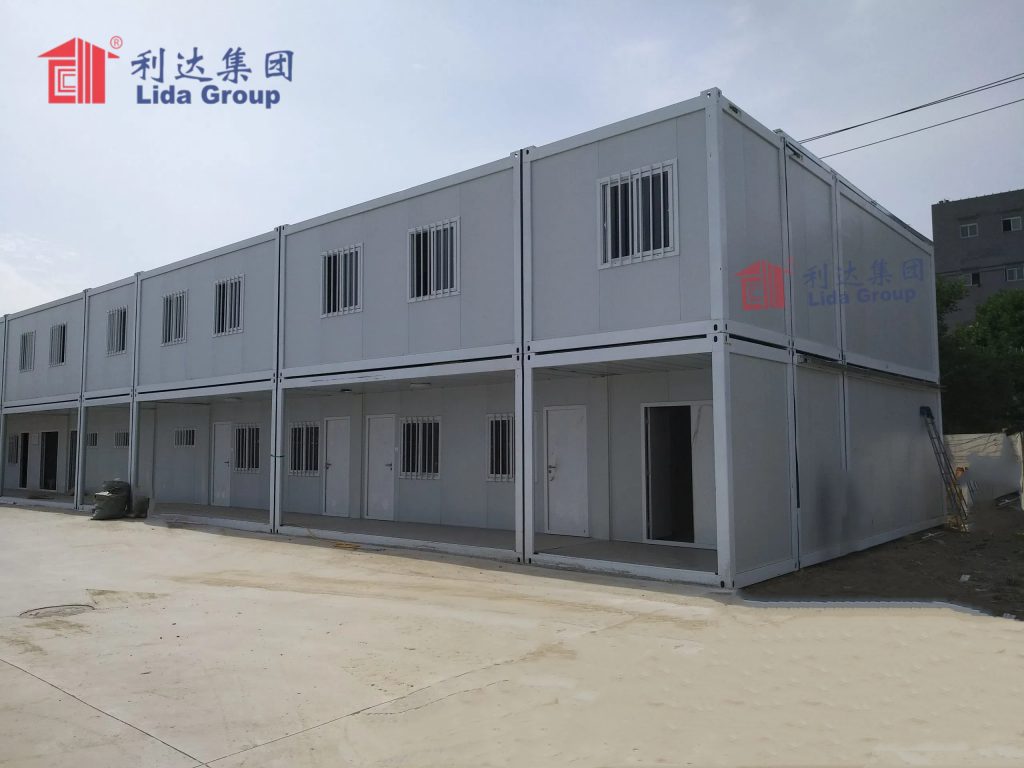

The two-year collaborative project commenced with design workshops bringing together Cambridge researchers, Lida engineers and materials scientists. Iterative computer modeling and physical mockups refined an integrated housing system addressing expedition requirements. At its core was use of refurbished 40-foot shipping containers as strong, standardized building blocks adapted internally to function as wet labs, dry labs, living quarters, workshops and multi-use spaces.

Externally, Lida Group’s engineers proposed a novel “Clip-Skin” modular facade system. Drawing on experience producing large insulated panels for emergency shelters, they developed lightweight composite sandwich structures with optimized thermal performance. Constructed from rigid foam cores laminated between fiberglass-reinforced plastic skins, Clip-Skins weigh under 15kg/m2 yet provide exceptional structural strength and insulation values. Design refinements included flush-mounted windows, vents and integrated photovoltaic panels.

An important innovation was the Clip-Skin connection interface. Consisting of aerospace-grade aluminum extrusions precision-machined to mate with flanges on container frames, Clip-Skins simply “clip” into place without tools or skilled labor. This “IKEA-style” system allows rapid on-site assembly and reconfiguration by small field teams. Internal layouts also leverage “plug-and-play” prefabricated modular components like workbenches, bunks and appliance units. With the Clip-Skin shell and standardized internal fittings, the resulting housing prototype achieved fully demountable, scalable construction.

Prototype manufacturing commenced with Lida Group’s facilities in Shenzhen mass-producing Clip-Skin panels and modular furnishings according to Cambridge specifications. Twenty refurbished 20-foot shipping containers were adapted internally to serve specified laboratory,workspace and living functions for groups of 4-6 personnel each. Completed sub-assemblies were transported to a test site at Lida’s experimental campus where Cambridge researchers provided on-site collaboration.

There, a full-scale prototype housing deployment was rapidly erected to validate the integrated system design. Twelve containers were connected using the Clip-Skin facade, forming three insulated structural zones accommodating 60 researchers. Power came from rooftop solar arrays tied to batteries while a rainwater catchment and treatment plant provided independent water and wastewater recycling. Heating and cooling was driven by a ground-source heat pump system leveraging the site’s temperate climate. Within only 5 days, a fully-serviced 84m2 laboratory-expedition housing complex was constructed entirely from container modules and Clip-Skins without heavy equipment – an unprecedented achievement for a project of this scale.

Over subsequent months Cambridge scientists inhabited and extensively tested the prototype deployment under real-world operating conditions. Feedback captured centered on technical performance, livability, maintenance and deployability metrics crucial to remote field feasibility. Climate regulation through hot summers and cold snaps exceeded expectations, with Clip-Skins proving highly insulative yet breathable. Interior spaces flexibly accommodated evolving experimental setups via adjustable temporary walls. Independent power, water and waste systems functioned reliably with minimal operator intervention.

Modular scaling allowed a second housing “cluster” to be seamlessly integrated within 24 hours using additional containers and panels kept on standby. Disassembly and storage packing likewise achieved in a single shift validated rapid setup/teardown viability. Only very minor design refinements were recommended, primarily focused on enhancing ergonomics and access provisions to accommodate full range of end users including elderly or mobility-impaired personnel. Overall, the system exceeded functional targets in all test criteria according to Cambridge researchers.

With the promising prototype validation complete, Cambridge engineers worked closely with Lida Group to refine the expedition housing design based on feedback. Key changes included adjustable workstation fittings, larger egress points, and lever-operated window openings. Additional testing under extreme winter conditions in Siberia further optimized Clip-Skin insulation performance prior to production. Manufacturing capacity was also expanded at Lida facilities to support anticipated scientific demand.

Following two years of collaborative development and trials, Cambridge researchers declared the modular expedition housing system fully validated for field deployment. The first production models are now establishing remote research outposts worldwide in previously inaccessible regions. Articulated transport containers loaded with Clip-Skin kits, laboratories and living quarters are delivered via charter aircraft and ships. On-site, small teams quickly assemble fully-serviced complexes able to support expeditions of 6-24 scientists over 6-18 month durations.

Early feedback from inhabited research stations in the high Arctic, African rainforests and Himalayas has validated livability, robustness and logistical feasibility of the portable housing solution in the most extreme environments. With basic setups assembled in under a week, scientific programs not previously considered due to large infrastructure needs can now sustain long field seasons thousands of kilometers from centers of habitation. Standardized connections enable easy expansion or downsizing on demand. Maintenance requirements are greatly simplified.

Cambridge and Lida Group look forward to ongoing collaboration refining the system to support full spectrum of scientific applications from 6-month ecology missions to multi-year remote Arctic monitoring. Additional specialized laboratory components like cleanrooms and aquaculture labs are also under development based on emerging research priorities. It is envisioned production capabilities may one day support deployments of 100+ personnel complexes for specialized big science initiatives like under-ice ocean drilling programs.

In conclusion, the collaboration between Cambridge material scientists and Chinese engineering firm Lida Group has yielded a breakthrough demountable modular housing solution fulfilling a critical unmet need in field research logistics. Leveraging cargo containers, energy efficient composite building skins, and standardized interface technologies, it enables construction of fully equipped research stations virtually anywhere in the world within a fraction of time and cost of any previous alternative. Capable of supporting diverse long-term scientific programs in even the most extreme natural environments, this pioneering system has the potential to open new frontiers in expeditionary research once considered unachievable due to lack of suitable infrastructure. With ongoing refinement, it may establish next-generation remote living and working complex standards accelerating insights across broad spectrum of scientific disciplines.

Related news

-

Film production chooses portable prefabricated housing encampments from Lida Group for location crews utilizing durable insulated wall panel dorms and multi-use spaces.

2024-10-21 17:30:15

-

Infrastructure contractor taps Lida Group to supply portable prefabricated camp complexes for migratory construction crews featuring foundationless housing constructed using structural insulating wall panels

2024-10-21 14:57:24

-

Municipalities select durable steel structural facilities from Lida Group to house emergency response fleets and equipment protected from natural disasters.

2024-10-17 15:55:51

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com