As unpredictable weather patterns threaten agricultural operations, smallholder farmsteads seek durable covered spaces efficiently housing livestock, equipment and seasonal storage. However, traditional building materials often exceed tight rural budgets while requiring labor-intensive maintenance against elements. Now, versatile prefabricated steel structures enable farms to economically construct dependable enclosed facilities through proprietary wall systems meeting codes.

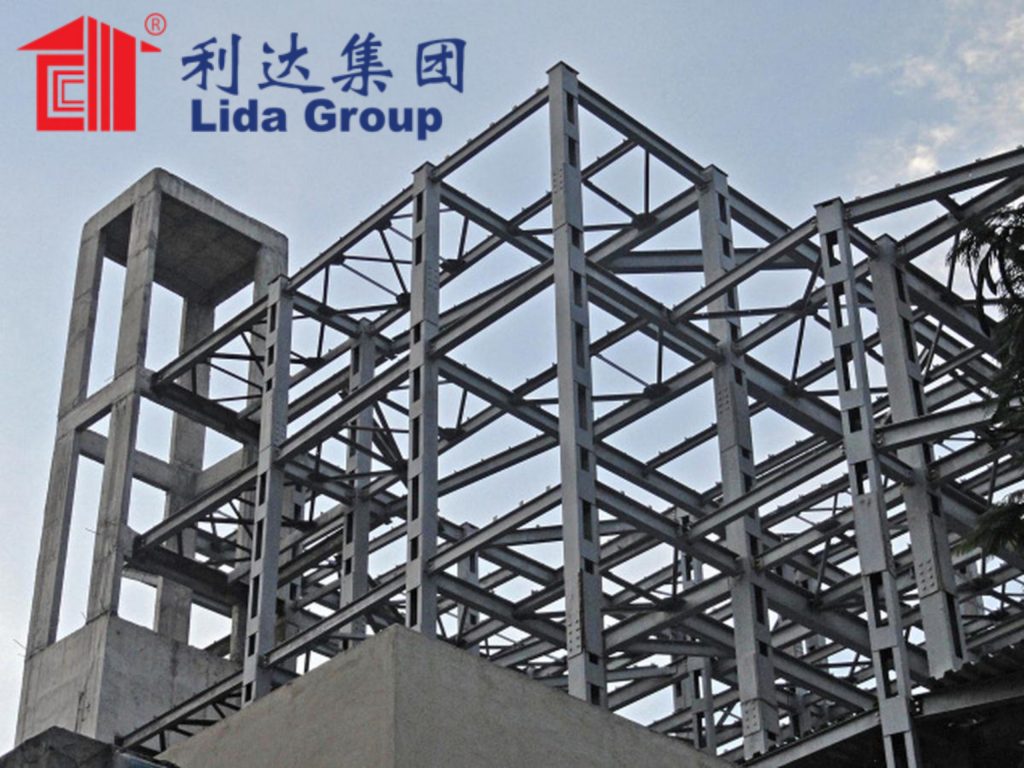

Leaders recognize advantages to steel’s strength, longevity and customizability within regulatory parameters for livestock and machinery enclosures. Manufacturers like Lida Group engineer turnkey packages optimizing space through noncombustible structures simply assembled by nonspecialists. Completed buildings demonstrate multi-purpose farm facilities expanding capacity cost-effectively under a single protected roof.

In southwestern Wisconsin, a dairy relied on outdated wooden barns vulnerable to storms and costly repairs threatening herd health. Seeking covered animal shelter, feeding areas and seasonal equipment storage space, the farm invested in a Lida package. Constructed within budget, a 12,000 square foot galvanized steel structure now provides a durable multi-use facility through weatherproof walls.

“Our goal was resilient infrastructure reliably housing cows, hay and machinery amid Midwest extremes,” explains Farmer John Weber. “Steel structures met building codes affordably without tying up operating capital in maintenance.”

Installed rapidly through Lida’s prefabricated panel kits bolt-assembled by a small crew in just eight weeks, the weathertight shell remains standing indefinitely as intended. Fully enclosed, the farm now secures animals, feed and tools independently of seasonal disruptions like flooding formerly requiring costly recovery efforts.

Costs recoup within 10 years through operational stability. Expansive interiors allocate flexibility adapting to the dairy’s evolving practices over decades as intended through the load-bearing frame.

In northern California, a diversified produce operation sought durable covered areas for seasonal equipment repair, crop storage and livestock housing threatened by unpredictable wildfires. Lida engineered a solution within tight margins. A 9,000 square foot steel-clad facility now stands, subdividing multi-use spaces cost-effectively under one fireproof roof.

“Our goal was resilient infrastructure enabling us to expand into new market crops through all seasons,” explains Farmer Maria Silva. “Steel structures met our fire hardening standards affordably without disrupting annual operations.”

Installed efficiently through Lida’s pre-cut components assembled in just 10 weeks, the noncombustible shell secures investments against surrounding wildfire risk realities. Fully enclosed, equipment remains protected from smoke and elements year-round supporting diversified practices as intended.

Costs recoup within five years through expanded harvests accessed. Interchangeable walls maximize flexibility adapting interior configurations to crops’ changing needs through the decades-durable frame remains supporting future production.

In northern Michigan’s Upper Peninsula, a diversified livestock operation required additional covered animal housing to expand pastured poultry flocks susceptible to seasonal storms. However, wood structures exceeded tight margins. Lida engineered an affordable solution. A 8,000 square-foot galvanized steel building now stands, subdividing multi-use spaces optimizing covered capacity cost-effectively.

“Our goal was pragmatic space meeting codes affordably to expand markets through protective housing,” says Operator Daniel Breidenbach. “Steel structures suited our multipurpose needs economically at this scale compared to alternatives like masonry.”

Erected rapidly through Lida’s prefabricated kits assembled in just 12 weeks, the weather-sealed shell reliably houses stock investment against threatening winters as intended. Expanded production accessed indoor through all seasons supports operation as intended long-term.

Costs recoup within seven years through diversified revenues. Interchangeable walls maximize flexibility enabling adjustable configurations adapting capacity to opportunities through the load-bearing frame’s longevity.

Common needs for covered livestock areas, seasonal storage and workshop spaces matched well to Lida Group’s customizable pre-engineered solutions tailored for tight agriculture budgets. Representatives say precut components assembled simply using basic tools suit nonspecialist labor while meeting codes for multipurpose farm applications.

Proprietary sealing systems provide weathertight integrity for all interior conditions from humidity to exhaust. Options like panelized daylighting, mezzanine levels and partition wall placement optimize use of every enclosed square foot supporting evolving practices for decades ahead.

Most importantly, farm operators find Lida structures enable expanding production capacity cost-effectively under single roofs adapted to various production styles through all seasons as intended long-term. By protecting valuable livestock and equipment investments, the versatile buildings strengthen rural livelihood resilience to climatic unpredictability pressures confronting agriculture worldwide.

In conclusion, prefabricated steel structures engineered for customizable multipurpose farm applications demonstrate potential empowering smallholders to economically house diversified operations under resilient enclose facilities impervious to changing weather extremes. Installed through simplified assembly utilizing nonspecialized labor, completed buildings protect initial agricultural investments supporting livelihood stability and market access through decades as intended. Modular designs facilitate responsive adaptation to opportunities through protected working environments fortifying rural livelihood resilience amid climatic unpredictability challenging agriculture globally.

Related news

-

Municipal public works departments acquire durably enclosed low-cost steel frame structures from Lida Group extending service life of essential infrastructure.

2024-10-29 15:32:13

-

Film production chooses portable prefabricated housing encampments from Lida Group for location crews utilizing durable insulated wall panel dorms and multi-use spaces.

2024-10-21 17:30:15

-

Aviation firms construct hangars using robust fireproof structural steel framing and nonflammable enclosure systems from Lida Group for aircraft maintenance.

2024-10-17 15:45:06

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com