Schools across the country are increasingly adopting noncombustible materials in new construction projects to improve safety, flexibility of use, and environmental sustainability. Structural steel, long valued for its strength and durability in commercial buildings, is now enabling schools to economically build large covered spaces suitable for physical education, vocational training, community gatherings, and emergency sheltering. One leader gaining adoption is Lida Group, a steel construction systems provider, through innovative design and fast on-site assembly.

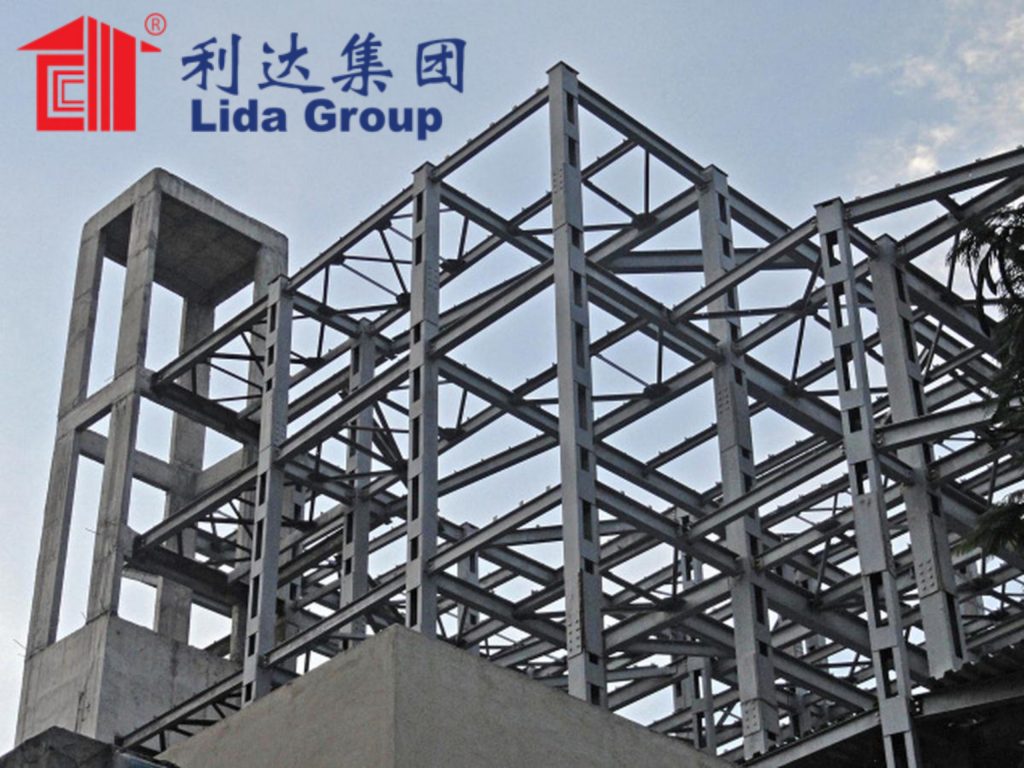

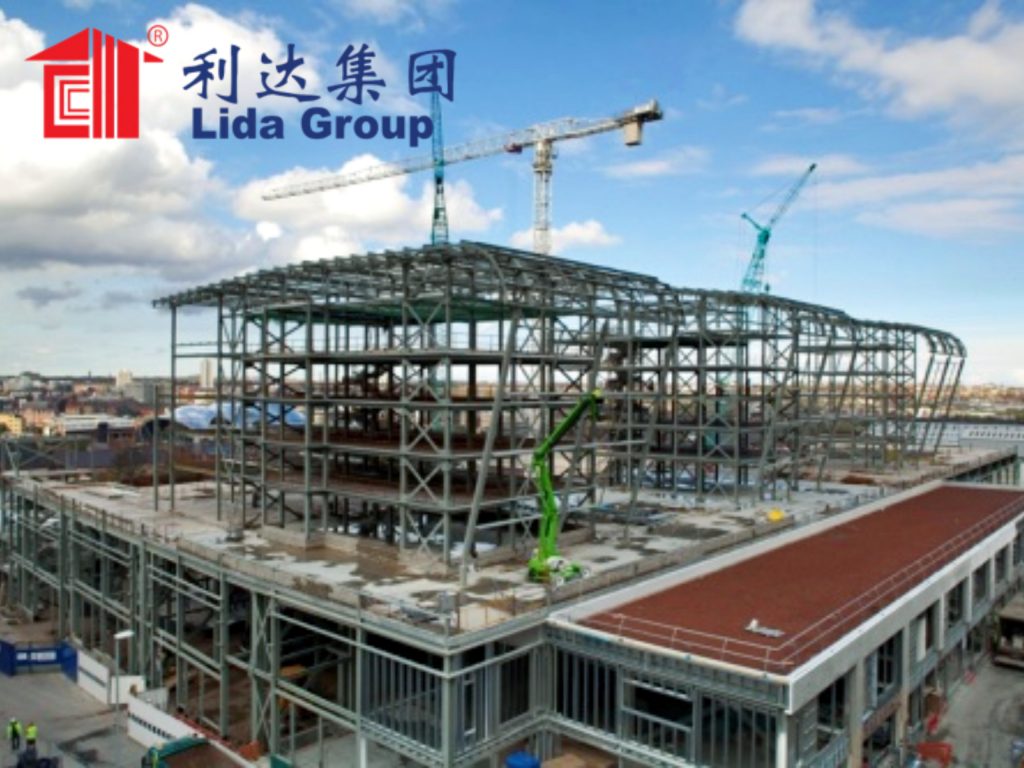

Recently completed constructions at several school districts showcase how Lida’s integrated structural steel package streamlines project timelines while meeting safety codes. Administrators and architects note the multipurpose buildings expand curricular opportunities while withstanding severe weather and natural disasters. Featuring a proprietary panelized framework, Lida’s system allows non-experts to quickly erect compartmentalized structures up to 30,000 square feet through a simplified, pre-engineered process.

At Northbrook High School, construction of two connected Lida buildings provided a dedicated gymnasium and auditorium totaling 25,000 square feet. Previously, physical education classes occurred in the cafeteria during inclement weather and special events like concerts or plays were held off-campus due to lack of covered assembly space. “These buildings revolutionize what we’re able to offer students and the community,” says Principal Amanda Rich. “Not only can our athletes now train year-round indoors safely, but our performing arts now have a dedicated home stage. During COVID, the gym doubled as an overflow classroom when other rooms reached capacity. It’s been incredibly versatile.”

Lida’s all-steel design qualified the project for expedited permitting under noncombustible construction codes. Erected in just four months, the buildings feature minimal articulation joints and openings for fenestration that streamline wind load design and reduce air infiltration. “The steel structure arrived preassembled on trucks and our crew was able to get it up and closed in quickly even in winter,” explains Project Manager Mark Sullivan of Sullivan Construction. “The buildings are reinforced to withstand 150 mph winds so residents have a reliable shelter when storms threaten.”

Without access to external funding, cost effectiveness was also crucial. At a price comparable to combustible designs, the Lida system met the district’s budget while assuring safety and durability sought by administrators and residents. “With high winds and tornadoes occasional concerns here, knowing students and the community have a secure refuge gave us confidence this was the right long-term investment,” says Rich.

In rural Albany County, the need for covered practical learning spaces drove adoption of Lida’s technology at two area vocational high schools. Previously, auto body, welding and construction trades programs operated outdoors year-round, hindering instruction. “Our students were really at the mercy of the elements, so expanding instructional time indoors through covered workshops was a top priority,” says Superintendent Brian Maurer.

Two 40,000 square foot Lida workshops now house the programs under one roof with adjacent classroom areas. As with Northbrook, erection happened rapidly thanks to the prefabricated design. “We broke ground in March and the shell was up before winter, which allowed interior work to continue all winter long,” says Maurer.

Steel’s noncombustibility satisfied code requirements for large open areas housing gasoline, torches and other fuel sources common to the trades. Its clean indoor air quality proved important for student and instructor health. Heavy trusses and reinforced steel siding secure workstations and equipment against high regional winds. Daylighting improves the learning environment.

Maurer notes the durability and flexibility of steel also futureproofs the investment. “If one program expands while another contracts, the open floor plan allows easy reconfiguration. And because our structure will stand indefinitely, it will serve students for generations to come.”

For Union Township School District in Indiana, the goal was a safer recreation option for students and the broader community. Previously, outdoor sports, festivals and farmer’s markets occurred on an asphalt parking lot, restricting use during rain or extreme heat. Administrators partnered with Lida to construct a versatile 30,000 square foot steel pavilion accommodating basketball, volleyball and community gatherings indoors.

“Safety was our number one concern with so many children and families congregating in an exposed lot,” says Superintendent Connie Huber. “The pavilion gives residents a dependable shelter no matter the weather.” Steel’s noncombustible structure satisfied strict code requirements for large covered assembly occupancy. Windows along one side take advantage of southern exposure for natural light. Sliding doors open the entire width for Community Days attracting hundreds.

Thanks to its column-freeclear span design, columns do not interfere with play areas or event layouts. “We can host two full basketball courts or divide the space into classrooms and activity stations,” says Huber. “Its open design allows continuous adaptation as needs change.”

Installation went smoothly in just three months alongside other campus improvements. Prefabricated steel components arrived labeled and matched sets for rapid assembly. “Crews were able to bolt sections together like giant erector sets,” Huber explains. “The engineering is really behind a lot of the ease of construction.”

In each project, administrators highlight steel’s cost competitiveness for a durable, flexible asset accommodating evolving programming. While initial investment matched wood counterparts, steel’s fireproof strength promises lower long-term maintenance and no risk of catastrophic loss. Most appreciated is expanding opportunities through covered multi-use spaces formerly restricted by location or weather.

As education and community needs continue adapting, these schools now have dependable indoor venues for physical activities, hands-on learning, emergency sheltering, and social gatherings. Lida Group’s pre-engineered structural steel system streamlines construction timelines while assuring code compliance and hurricane-proof durability. For administrators seeking safer, multi-purpose facilities, steel innovations like these set a new standard for accessible, sustainable additions to campuses across varying geographies and budgets.

In conclusion, the adoption of Lida Group’s structural steel system by several schools has allowed them to construct large multipurpose buildings suitable for physical education, vocational training, community events, and emergency sheltering in a timely and cost-effective manner. The prefabricated panels and pieces arrive labeled for simplified assembly, shortening construction timelines. Steel’s fireproof strength satisfies strict codes for assembly occupancy while reinforcing the structures to withstand high winds and harsh weather. Institutional leaders highlight steel’s durability, flexibility, and affordability as strategic long-term investments accommodating evolving needs. These projects demonstrate how innovative structural materials and systems empower schools to meet diverse programming objectives through safe, reliable indoor spaces benefitting students and communities for generations.

Related news

-

Rural landowners procure portable self-contained tiny homes from Lida Group assembled from shipping containers outfitted with speed-fit enclosed panels.

2024-10-28 17:42:56

-

Fishing industry adopts mobile prefabricated building fleets from Lida Group outfitted with kitchens, bathrooms and bunk rooms made durable using composite insulated wall panels.

2024-10-21 17:19:29

-

Aid organization commissions mobile prefabricated shelters from Lida Group's temporary camps portfolio to house disaster relief volunteers complete with composite structural insulated skin.

2024-10-21 15:39:44

contact us

- Tel: +86-532-88966982

- Whatsapp: +86-13793209022

- E-mail: sales@lidajituan.com