PRODUCT INFORMATION

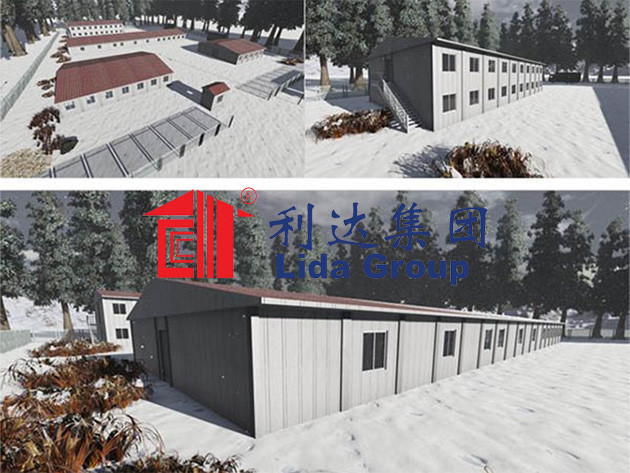

As a leading supplier of prefabricated steel structures, Lida Group designs and constructs modernized chicken layer houses to meet the exacting needs of poultry farms.

Lida Group’s prefabricated steel structure chicken layer houses incorporate modern design features for optimal functional performance. The steel frames have large clear spans to accommodate rows of layer cages with ample walkways for workers. High ceilings provide adequate ventilation and allow heat to rise efficiently.

Externally, steel cladding and metal roofing give the layer houses a contemporary and durable facade. Sleek roof lines and minimal overhangs minimize ledges where dirt can accumulate. The modernized exterior elevates the image of the farm.

Inside, fluorescent tube lights and LED fixtures provide uniform illumination for the birds. Air conditioning systems maintain ideal temperature and humidity levels for egg production. Automated feeding, watering and manure removal systems improve labour efficiency.

As experts in steel engineering, Lida Group designs the structural frames to withstand environmental stresses like high winds, snow loads and extreme temperatures. Advanced coating systems protect the steel from corrosion to extend the lifespan of the layer house.

Lida Group’s prefabricated construction approach assembles the steel structures faster with less disturbances to farm operations. Quick installation means lower down-time for farmers. The flexibility of modern steel framing also allows for future expansion or modification of the layer house layout.

Throughout the project, Lida Group works closely with farm owners to understand their specific rearing requirements and challenges. Structural designs are customized to optimize functional performance based on factors like breed size, feeding schedules and manure handling needs. Customer feedback is collected to continually improve designs and services.

In summary, by leveraging the advantages of modern steel structure and applying contemporary design approaches, Lida Group is able to transform traditional chicken layer houses into high performance facilities through optimized functional layouts, integrated automation systems and a stylized yet durable facade. Farmers benefit from higher productivity, animal welfare and brand image – all enabled by a Lida Group modernized steel structure layer house customized for their farm.

If you are planning to build a new layer house or upgrade an existing one, Lida Group has the expertise and experience to provide a customized prefabricated steel structure solution that precisely meets your farm’s unique needs and visions. Please contact Lida Group today to discuss your project requirements.

| 1.Steel Structure: | ||

| 1.1 | Steel column | 120x120x2.5 |

| 1.2 | Steel structure beam | C120x50x20x2.0 |

| 1.3 | Roofing Purlin | C140x50x20x2.0 |

| 1.4 | Wall purlin | C120x50x20x2.0 |

| 1.5 | Anchor bolts | M16 |

| 1.6 | Ordinary bolt | 4.8S,Galvanized |

| 2.Roof and wall: | ||

| 2.1 | Roofing-PU board | 100mm,40kg, 0.5/0.5mm, heather transfer≤0.021w/mk, anti press≥210Kpa; |

| Or Fiber glass board or EPS panel | OR100mm,60kg, 0.5/0.5mm, heat transfer≤0.028w/mk, anti press≥180Kpa | |

| Can be changed as per customers’ request. | ||

| 2.2 | ceiling upon the door | 100mm,40kg, 0.5/0.5mm, heather transfer≤0.021w/mk, anti press≥210Kpa; |

| OR100mm,60kg, 0.5/0.5mm, heat transfer≤0.028w/mk, anti press≥180Kpa | ||

| Can be changed as per customers’ request. | ||

| 2.3 | Exterior wall-PU board | 100mm,40kg, 0.5/0.5mm, heather transfer≤0.021w/mk, anti press≥210Kpa; |

| OR | OR 100mm,60kg, 0.5/0.5mm, heat transfer≤0.028w/mk, anti press≥180Kpa | |

| Rockwool board or EPS panel | Can be changed as per customers’ request. | |

| 2.4 | edge cover plate | 0.5mm steel plate |

| 3. Ceiling and Ground | ||

| 3.1 | gypsum ceiling-for room | 600*600*6mm, including frame |

| 3.2 | PVC ceiling-for toilet | PVC board |

| 3.3 | flooring tile | 600*600mm |

| 3.4 | Gutter | PVC |

| 3.5 | drainpipe | 80mm |

| 4. Door and window: | ||

| 4.1 | Exterior Door | light steel door.Can be changed as per customers’ request. |

| 4.2 | Interior Door | Sandwich panel door or light steel door |

| 4.2 | Window | PVC, with double glass 4+6+4mm |

| 5. Electric +water: | ||

| 5.1 | Electric cable | lighting 2.5mmm2, air conditioner : 4.0mm2 |

| 5.2 | PVC wire Channel | |

| 5.3 | light | 110V/220V,50HZ/60HZ, ceiling light |

| 5.5 | Switches | with junction box |

| 5.6 | Socket | 16A Universal Socket |

| 5.7 | water heater | Haier Brand(ES60H-X1(E)), 100L, twin-tubeheater, 3000W, heating temperature 75degree. Can be changed as per customers’ request. |

| 5.8 | Power distribution cabinet | box+switch+earth leakage protective device |

| 5.9 | bidet | including accessories |

| 5.1 | closestool | including accessories |

| 5.11 | washbasin | including the water pipe |

| 5.12 | shower | shower base, shower head, water mixture |

| 5.13 | water pipe | input and output water pipe |

Typical drawings of Lida Factory Price Modernized High Rise Prefabricated Steel Structure Construction For Chicken Layer House

Specification of Lida Factory Price Modernized High Rise Prefabricated Steel Structure Construction For Chicken Layer House

Send Your Message

Our team will use our experience to provide the professional services .